The Robotic Welding Advantage

In demanding manufacturing environments, efficiency and reliability are key factors to keep production running smoothly. Slowdowns due to tool changes, high operating expenses, and rigid welding systems can also significantly impact productivity and profitability.

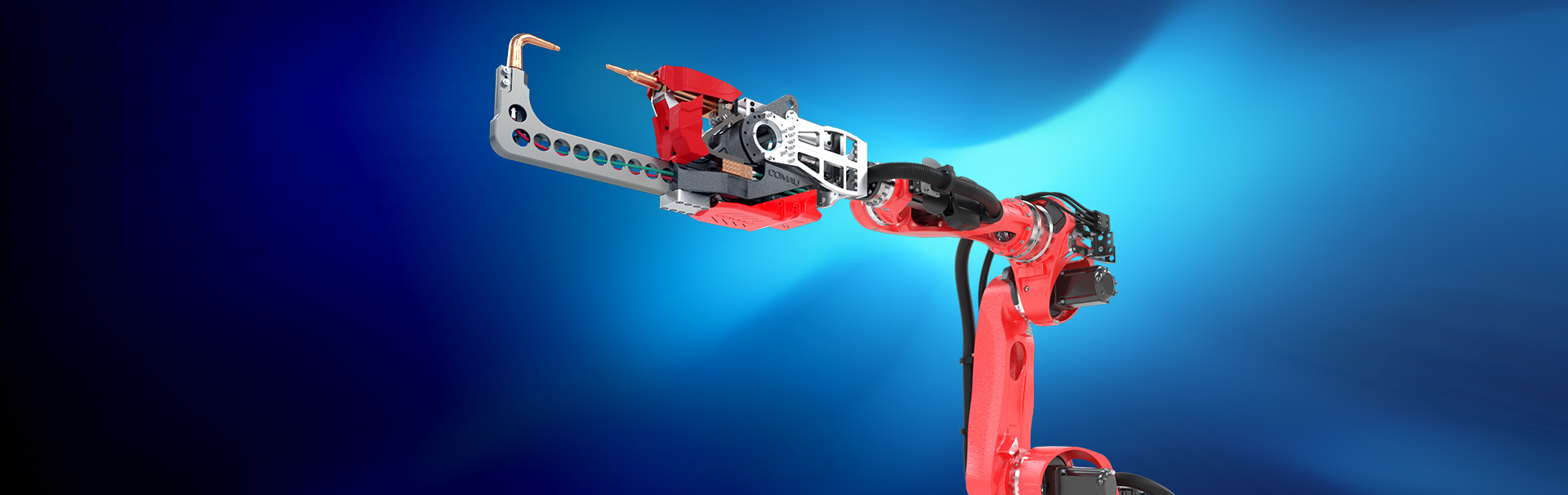

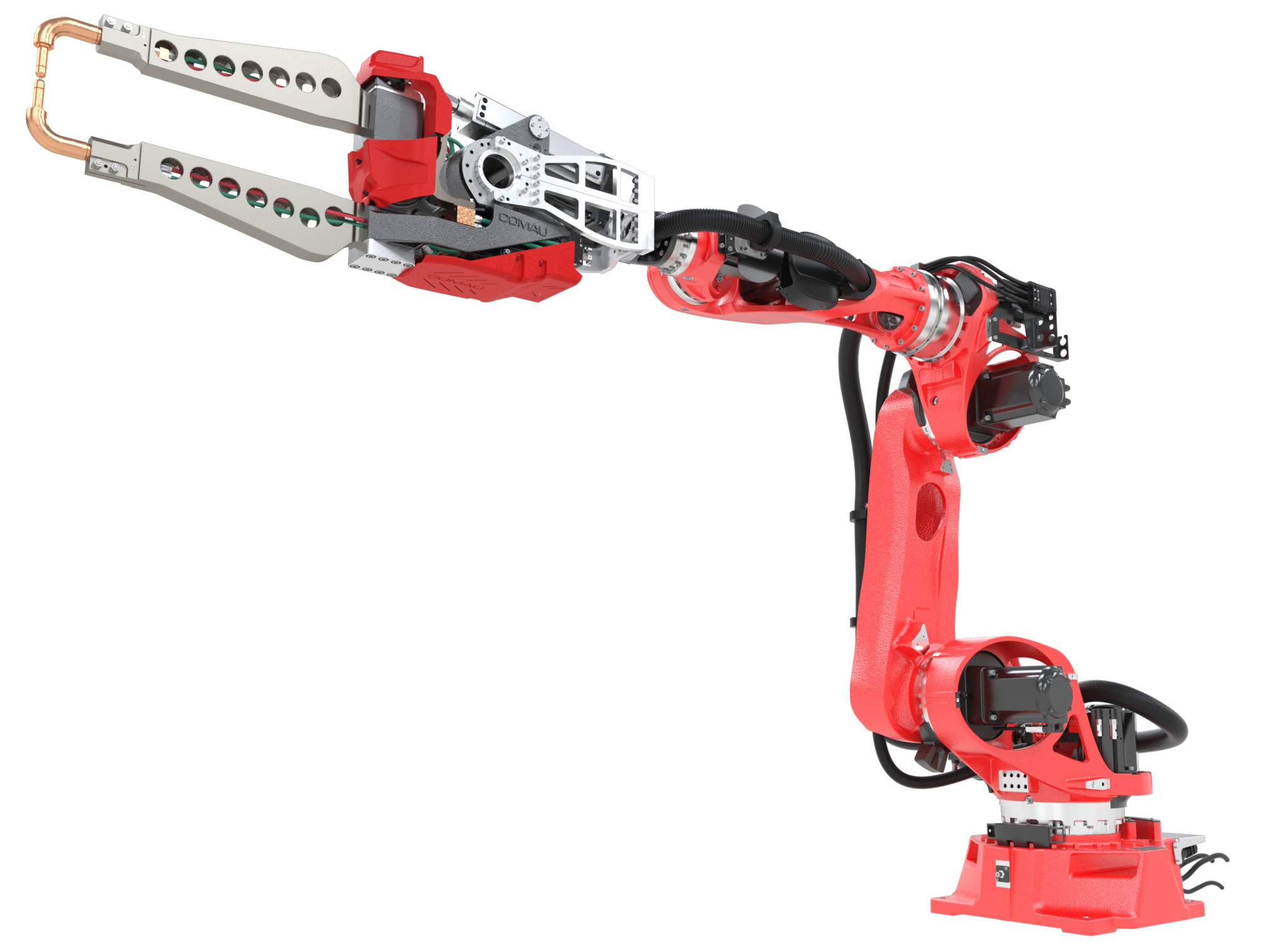

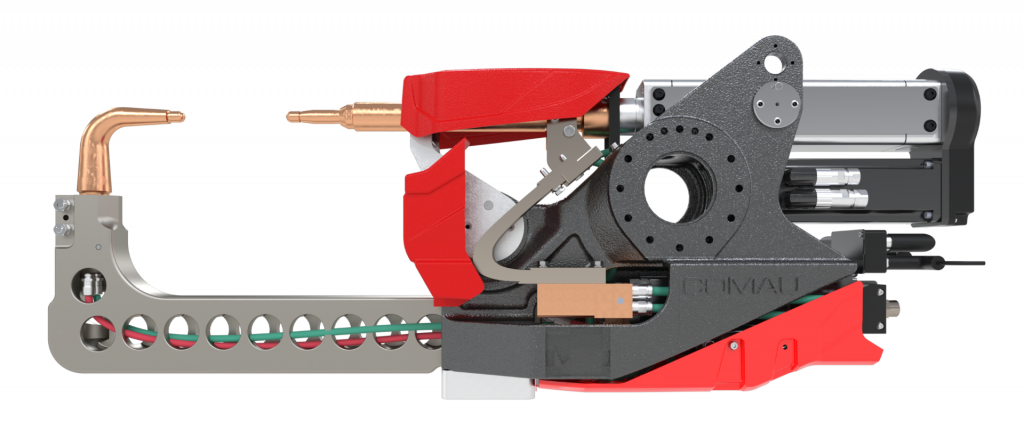

Comau addresses these challenges head-on with its new welding guns, an innovative solution designed for superior modularity, and rapid reconfiguration. The Comau all-new generation of welding guns, N-WG series, minimizes downtime, costs, and errors while maximizing welding operation performance. This enables manufacturers to achieve higher speeds, improved quality, and greater cost efficiency in their welding processes.

High-performance, reliable, customizable, and precise robotic welding

Presenting Our Welding Gun Family:

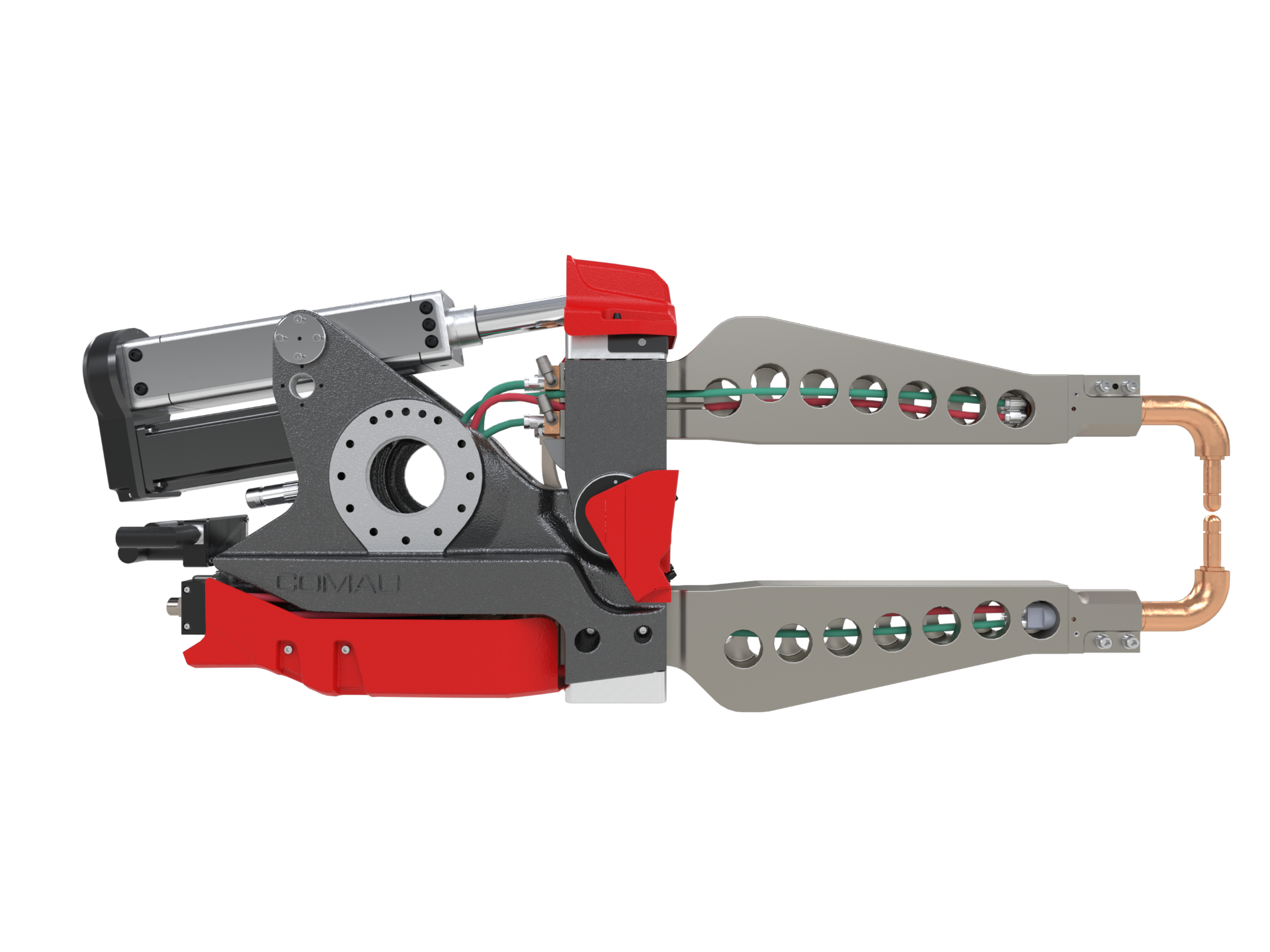

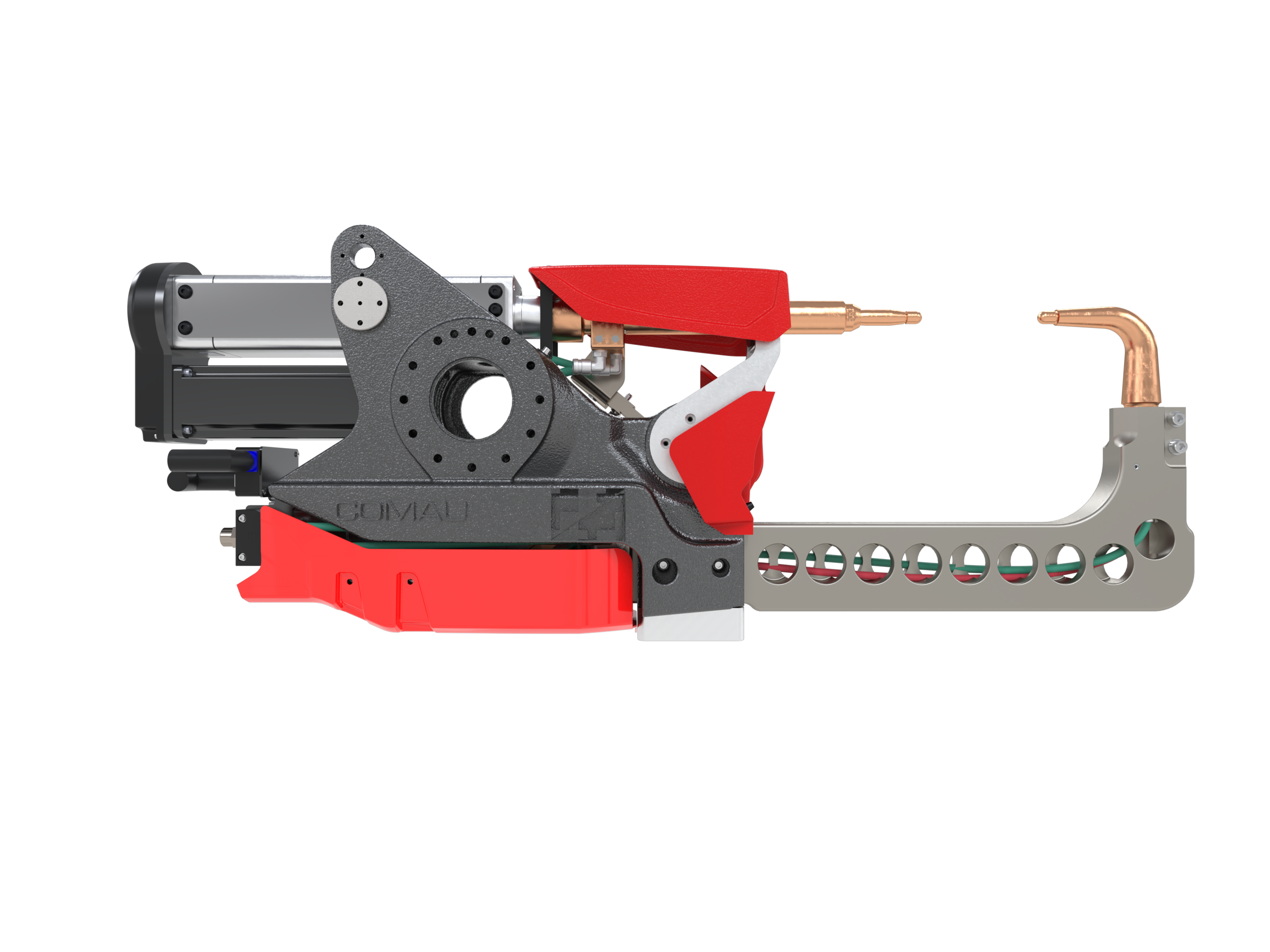

N-WG C-type / X-type (steel joint)

Comau’s N-WG welding guns represent a new paradigm in welding technology, designed with direct feedback from our customers. Our commitment to innovation and customer satisfaction is reflected in every detail, from the single body design that covers the entire range to the fast-change arm that eliminates production halts.

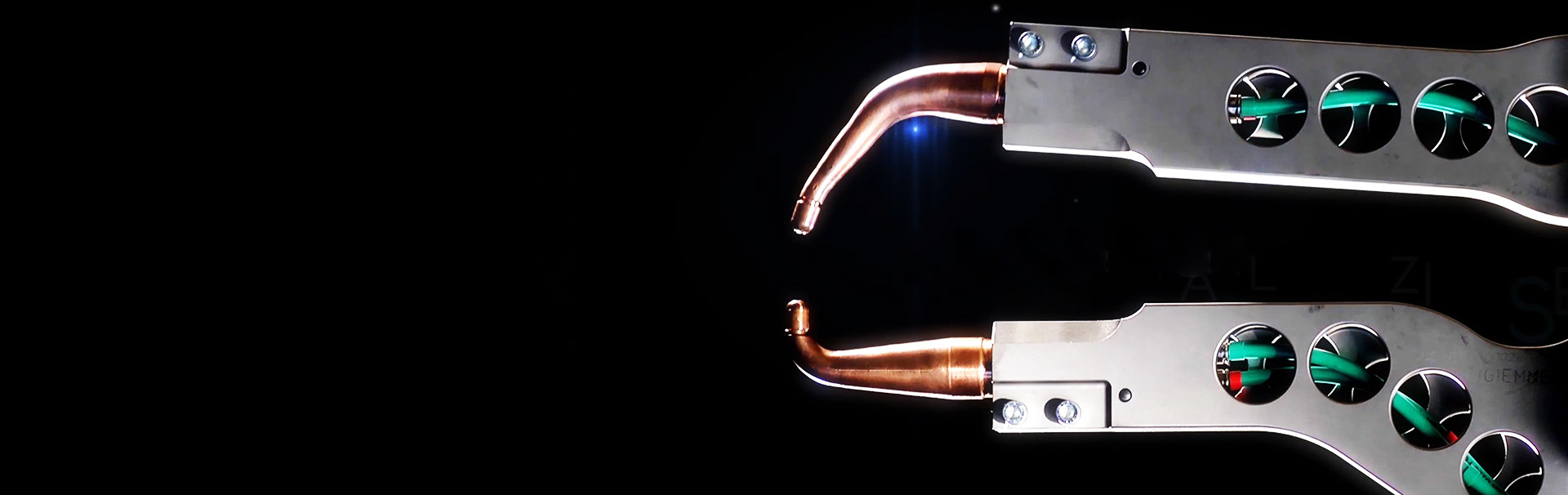

Comau provides a full range of standard gun arms (small, medium, large and extra-large). For specific requirements, Comau engineering supports customers in the modeling and designing of special gun arms. The 3D model shape can also be simulated and tested before the manufacturing launch to verify absolute process reliability.

This groundbreaking design ensures high-speed functionality, superior quality, cost-effectiveness, and exceptional process efficiency in automated welding.

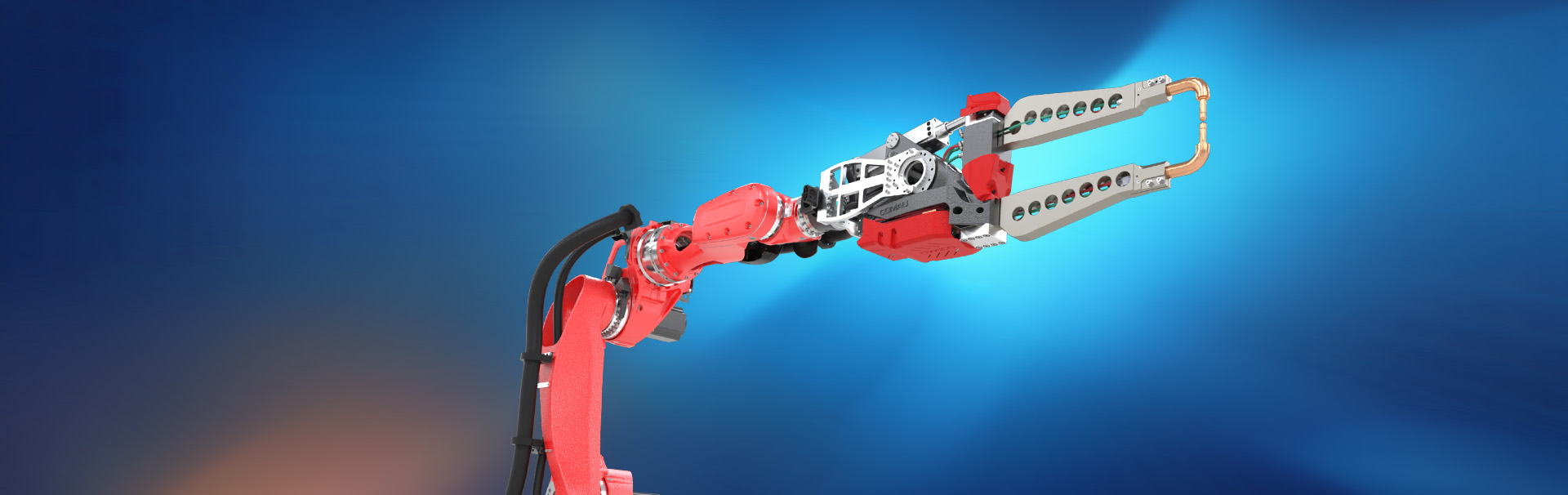

Fully integrated on Comau N-Series and NJ4 robots (welding machine)

Key Benefits of Comau N-WG Welding Guns

Modular and Symmetrical Design

Reduces spare parts and procurement lead times

Lower Total Cost of Ownership

Competitive initial investment and reduced operating, spare parts, and consumption costs

High Performance and Repeatability

Designed to deliver consistent performance day after day

Quick Arm Exchange

Facilitated by a new design with a dedicated clamp and modified gun arm structure

Fast Reconfiguration Capabilities

Easily switch between X and C types by changing a single module, pulley, and belt

Universal Mounting Positions

Top, back, bottom, side, 30°, and 60° mounting options.

Customization Options

Comau offers a range of standard and custom gun arms, with 3D modeling and simulation for process reliability

Integrated Solution

Seamless integration with Comau Robots and mountable on any robot brand

Welding Machines

a complete package designed to multiply the advantages of integrated

solutions.

Want to Know How The New Welding Guns

Fits Your Production Line

Two standard chassis (“C”, “X”) provide a light and compact solution, fully compatible with any robot brand with internal or external dressing

more information

book a demonstration

Technical Specifications

Comau welding guns are designed to deliver optimal performance and high repeatability, day after day, year after year.

| N-WG Specifications | |

|---|---|

| Body weight | 78 KG |

| MFDC Transformer | 100 KVA at 50% DC |

| Welding Force | X-type: 560 daNm C-type: 800 daNm |

| Actuator Max. Force | 20 kN |

| Transformer Type | ISO |

| Body Styles Number | 1 |

| Cooling Efficiency | X-type: up to 9 l/min C-type: up to 9.7 ll/min |

| Equalizing | by SW |

| Feedback for adaptive quality system | Voltage |

| Design life | 30 Mil. cycles |

| MTTR | 10 minutes |

| Cooling Requirement | 8 l/min series circuit |

- Unique body for standard and high-force

welding guns - Fast reconfigurability between X and C

- Fast arms exchange

- Lower Total Cost of Ownership

- Designed for simplified maintenance and

fewer spare parts - MTTR is less than 10 minutes

- Improved water flow, rationalized fittings

and a streamlined cooling system - Reduced energy and water consumption

- Design life 30 million cycles

Basic Configuration

- Comau Servo Actuator

- MFDC transformer for steel joint

- Robifix multi-contact primary power connection

- Connection Box for I/O management

- Distributor for water connection

- Bracket Standard types (for fixing the gun to the robot flange)

- Secondary voltage feedback for adaptive quality system (for steel)

Options

- Custom “Product / Process” special arms

- Special bracket design

- UL compliant Modular Covers

The robot and welding gun become one

Maximum Performance for High-Density Welding