Why and When to Integrate Collaborative Robots into Your Operations

In the modern manufacturing environment, efficiency, safety, and adaptability are crucial. Collaborative robots, or cobots, can represent faster lead times and reduce integration complexity while enabling human-robot interaction.

These cobots integrate into existing layouts, foster inclusive workspaces, reduce process variability, and can be rapidly redeployed for diverse applications, offering significant benefits in efficiency and adaptability.

Smarter Collaboration,

Seamless Integration

MyCo collaborative robots are ideal for businesses facing limited plant space, needing consistent speed aligned with human operators, and demanding flexible automation

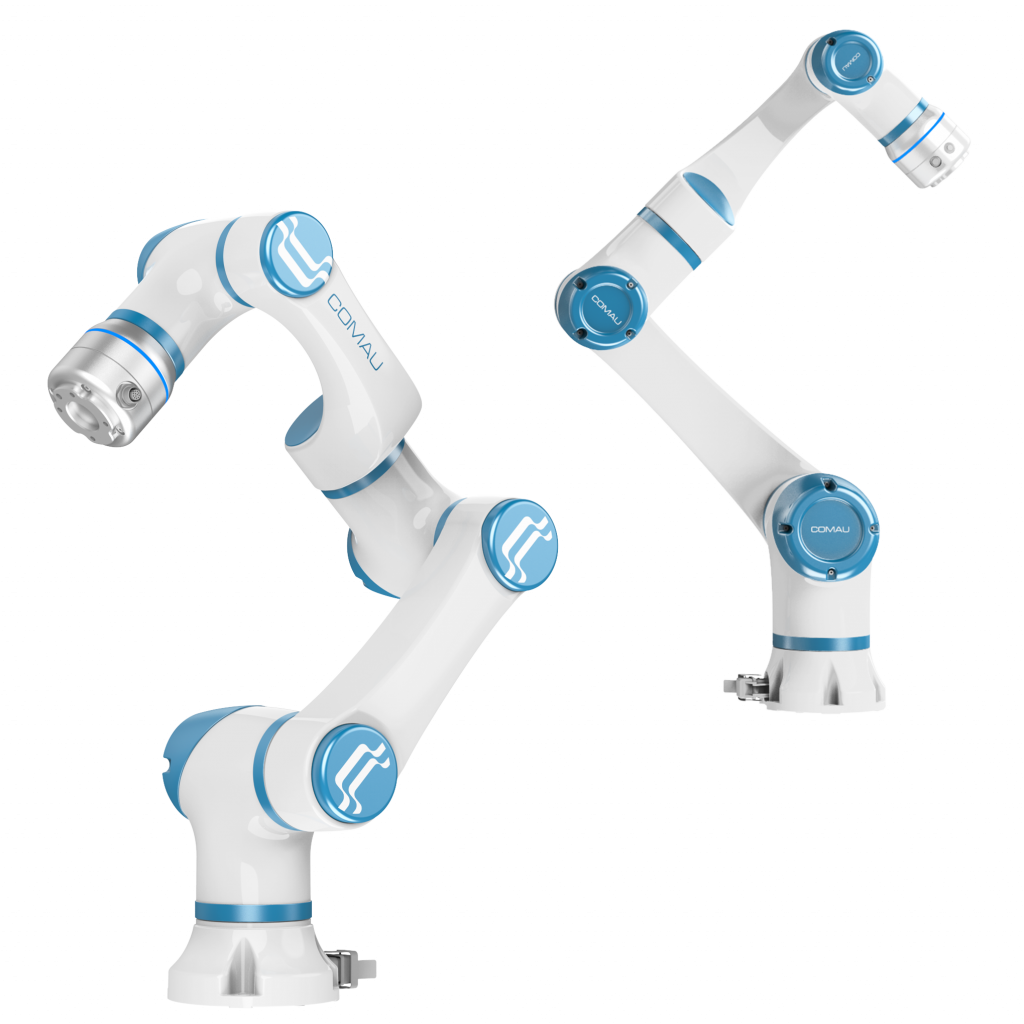

Introducing the Comau MyCo Cobots

Combining advanced collaborative safety features with ergonomic benefits, MyCo enables humans and robots to work side-by-side, enhancing employee well-being, optimizing floorspace, and supporting safer, more inclusive operations.

The Comau MyCo family of collaborative robots delivers a precise, reliable, and cost-effective automation solution designed for companies of all sizes. Engineered for quick installation, easy programming, and rapid redeployment, MyCo cobots significantly reduce integration complexity and support faster lead times.

MyCo Cobots

Real Benefits for Manufacturers

Variety of Models

A comprehensive range to suit diverse application needs

Fully Integrated with ROS/ROS2

Designed for advanced robotics in collaborative mode

Low Weight & Easy Deployment

Facilitates quick installation, integration and redeployment across different tasks

High Precision & Excellent Repeatability

Ensures consistent and accurate performance for demanding applications like Arc Welding

High Flexibility & Modular Design

Adapts to evolving production requirements with ease; Internal cabling

High Protection: IP54 (with optional IP66)

Against dust and water, ensuring durability in industrial environments

Easy & Fast Programming

Supports graphical programming and remote calling interface

Force Control Integration

Constant force control for perfect trajectory; Cartesian manual

guidance; Soft control with smooth free-drive teaching

Transform your manufacturing operations

with the Comau MyCo collaborative robot family.

Want to Know How Comau MyCo Cobots

Fits Your Production Line?

more information

book a demonstration

Why Choose Comau’s MyCo Cobots?

Technical support

& After Sales

Direct contact with our worldwide customer

No language barriers

50+ years of experience as

System Integrators

Vision Systems

Process and Simulation Skills

IoT

Industry 4.0 and 5.0

Partnerships with the main end-effectors brands

Standard Cell solutions

Realistic

industrial vision

The Collaborative Robot is an industrial object: it takes expertise and training

Both the application and the robot itself must be collaborative

MyCo Cobots Family Technical Specifications

The MyCo family offers six lightweight models with payloads ranging from 3 kg to 15 kg:

| Model | Weight | Payload | Reach | Power Consumption | Repeatability |

|---|---|---|---|---|---|

| MyCo-3-0.59 | 18kg | 3kg | 590mm | 100W | ±0.02mm |

| MyCo-3.5-0.95 | 26kg | 3.5kg | 950mm | 180W | ±0.02mm |

| MyCo-5-0.80 | 25kg | 5kg | 800mm | 180W | ±0.02mm |

| MyCo-8-1.30 | 45kg | 8kg | 1300mm | 350W | ±0.03mm |

| MyCo-10-1.00 | 43kg | 10kg | 1000mm | 350W | ±0.03mm |

| MyCo-15-1.30 | 60kg | 15kg | 1300mm | 600W | ±0.05mm |

All MyCo models feature 6 degrees of freedom, an IP54 dust and water protection rating (IP66 optional), and can be mounted on the floor, ceiling, inclined plane, or wall. They operate within a temperature range of 0-50°C and accept a power input of 100-240V AC, 50-60Hz.