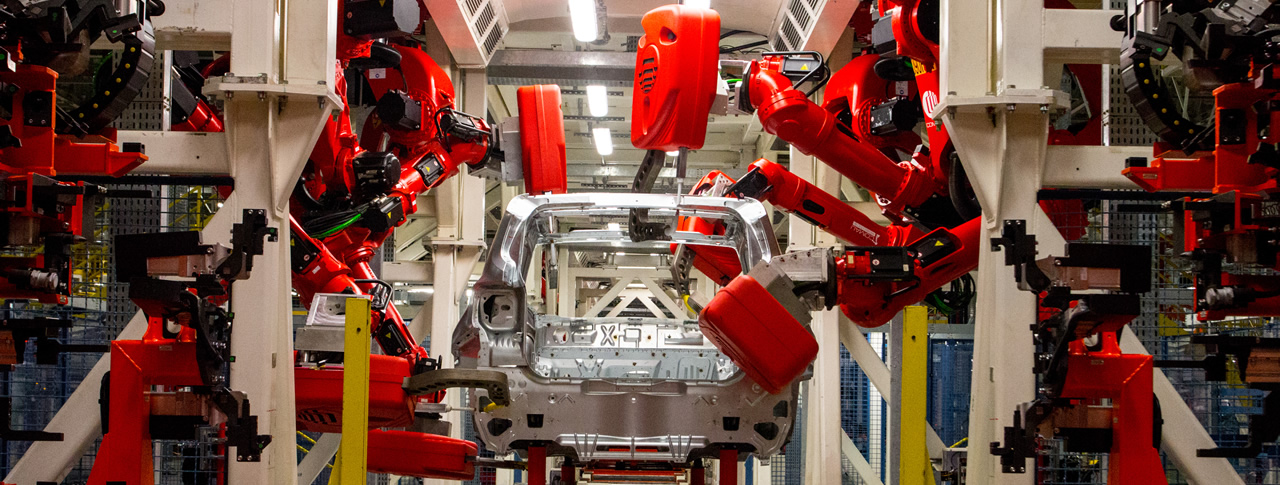

Robot Welding Guns

A complete range for every type of application in BIW for steel or aluminum joining.

Manual Welding Guns

A high level of standardisation for a complete welding cell suitable for pilot or production lines.

MFDC Welding Box

Compact design for multiple solutions, to ensure the highest spot quality.

Accessories

A wide range of optional components to complete the manual welding cell.

Spot Welding Machine – APC – RHEvo

Line Feeding

Products family which answer the need to feed the line.

LF18 Single Bay Rack

Simple and safety solution to pick and place the rack.

LF15 Lifting Turn Table for Racks

System developed to optimise floor space and cycle time.

AVT: Adjustable Versa Trolley

Safety rack trolley to avoid forklift by optimising the logistic flow.

Vision Systems

Innovative products and turnkey solutions for robot guidance, measurement and inspection.

Robot Guidance

Advanced solutions based on visual recognition technology with 3D single camera for deracking and high precision applications.

Measurement

High repeatability measurement for quality control on Gauging, In-line and Gap & Flush applications.

Inspection

Innovative solutions for quality monitoring on joining technologies.