Flexible Robotic Automation for Cutting, Sealing & Welding Applications

In today’s manufacturing landscape, precision, flexibility, and simplicity are essential.

Comau’s NJ-series robots, integrated directly into CNC processing environments, deliver fully automated solutions for taping, water-cutting, ARC welding, and more—ensuring optimized performance with minimal system complexity.

This seamless combination of robotics and CNC control delivers optimized performance, reduced complexity, and greater flexibility, even for multi-process and multi-product production lines.

Integrated Robotic Automation in CNC Manufacturing

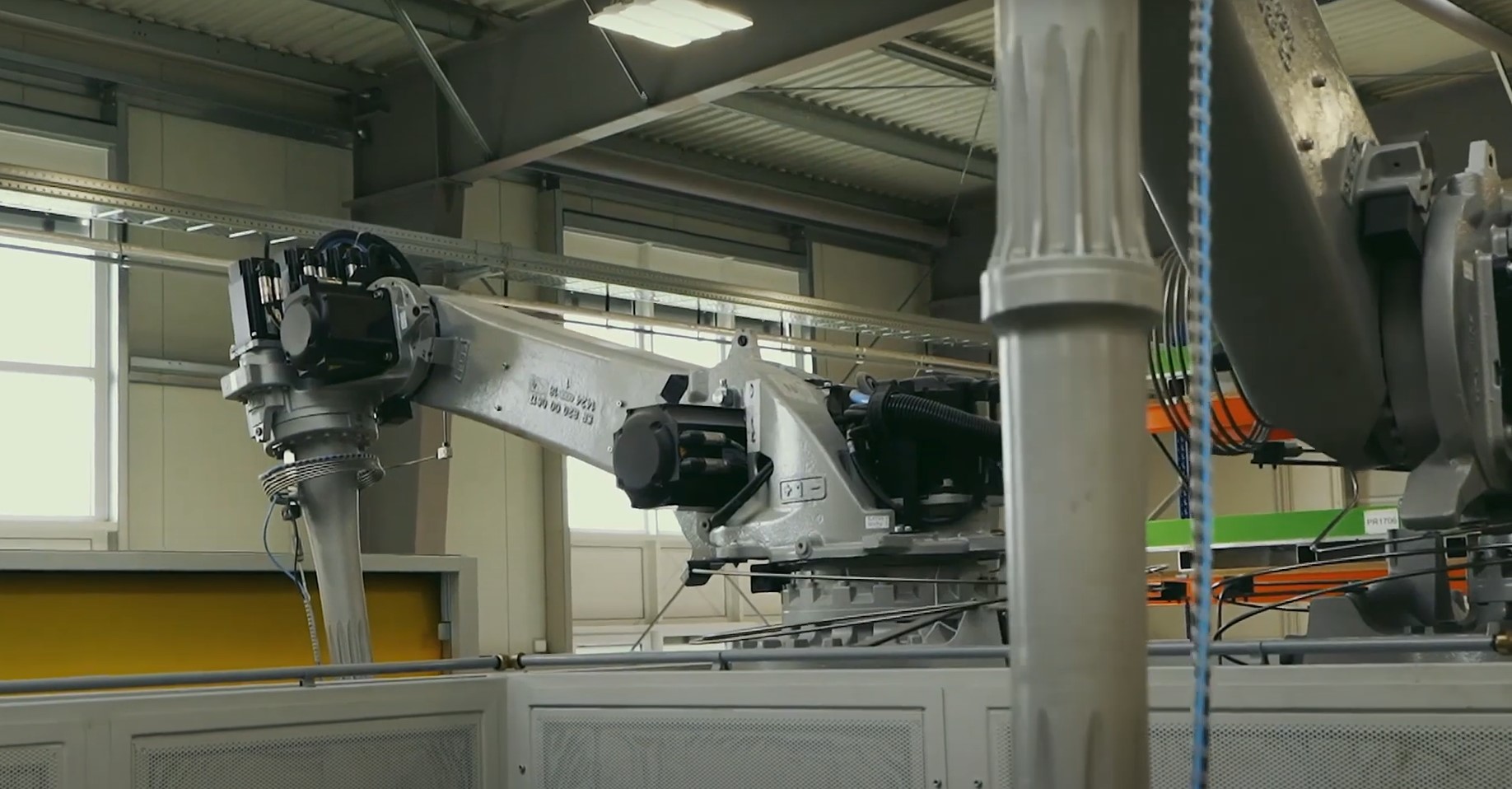

This video showcases a CNC robotic cell powered by Comau NJ-16-3.1 robots, integrated with Siemens Sinumerik RunMyRobot/DIRECT technology.

Case Study: CNC Robotic Cells with Integrated Comau Technology

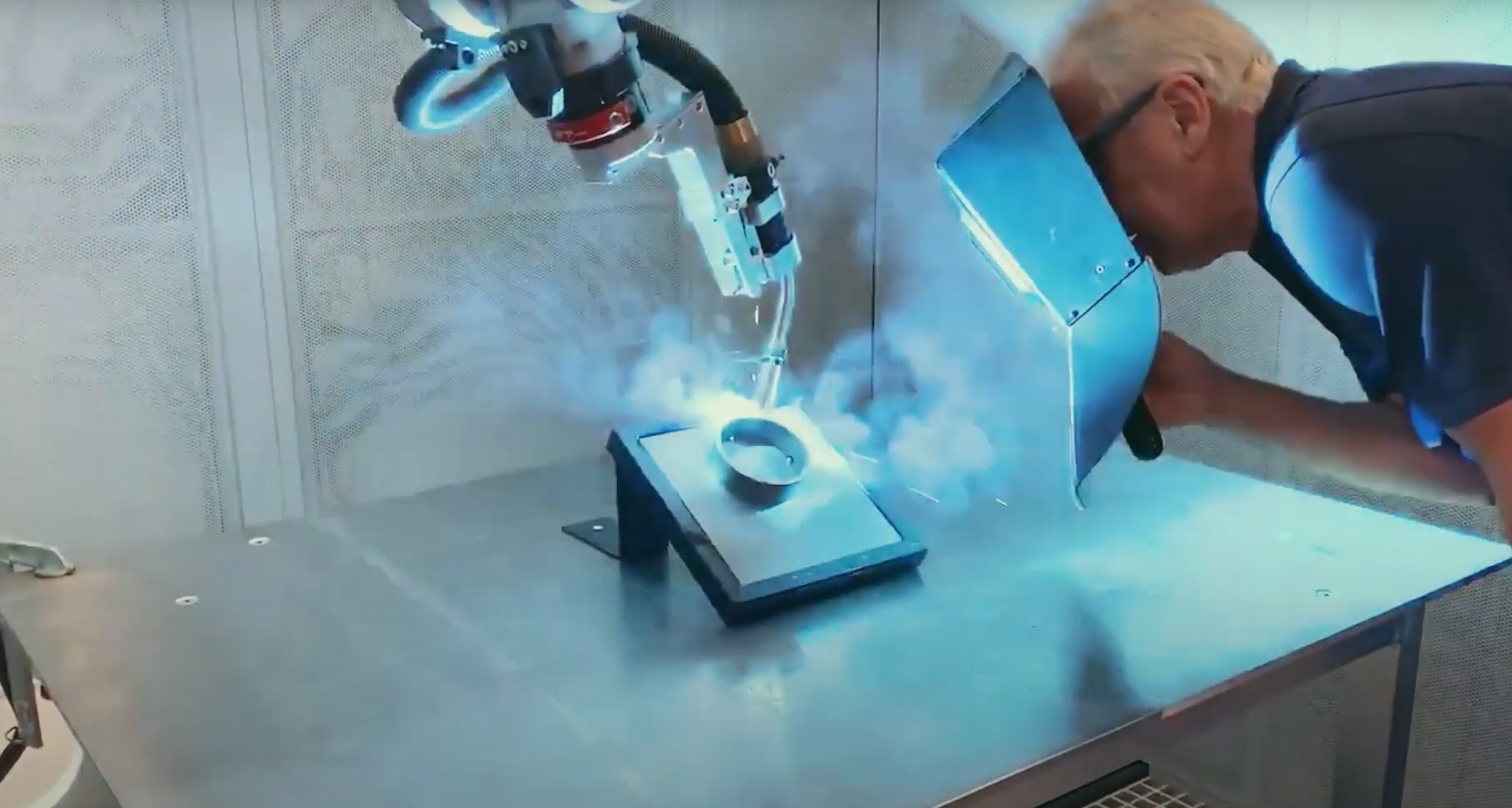

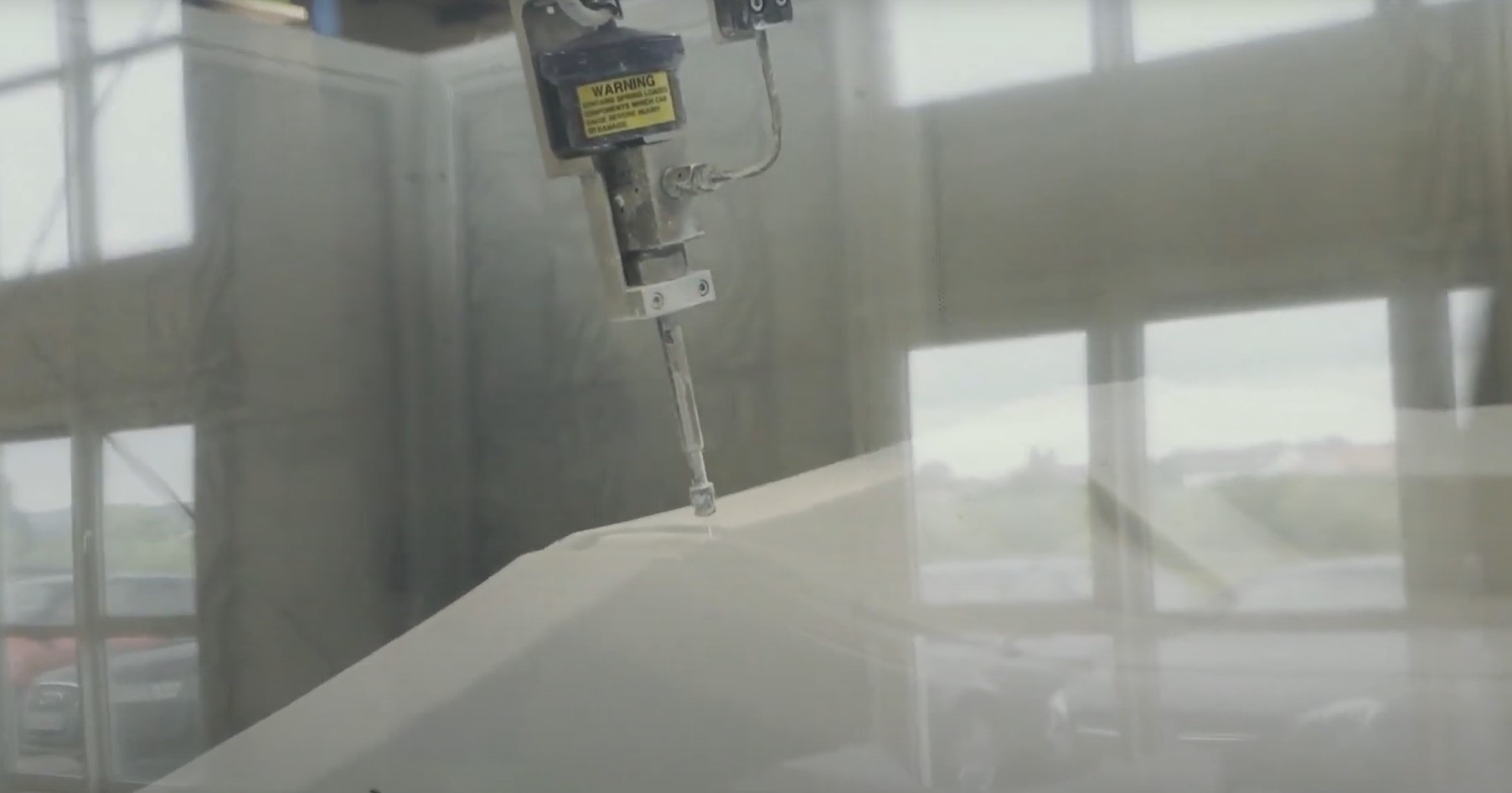

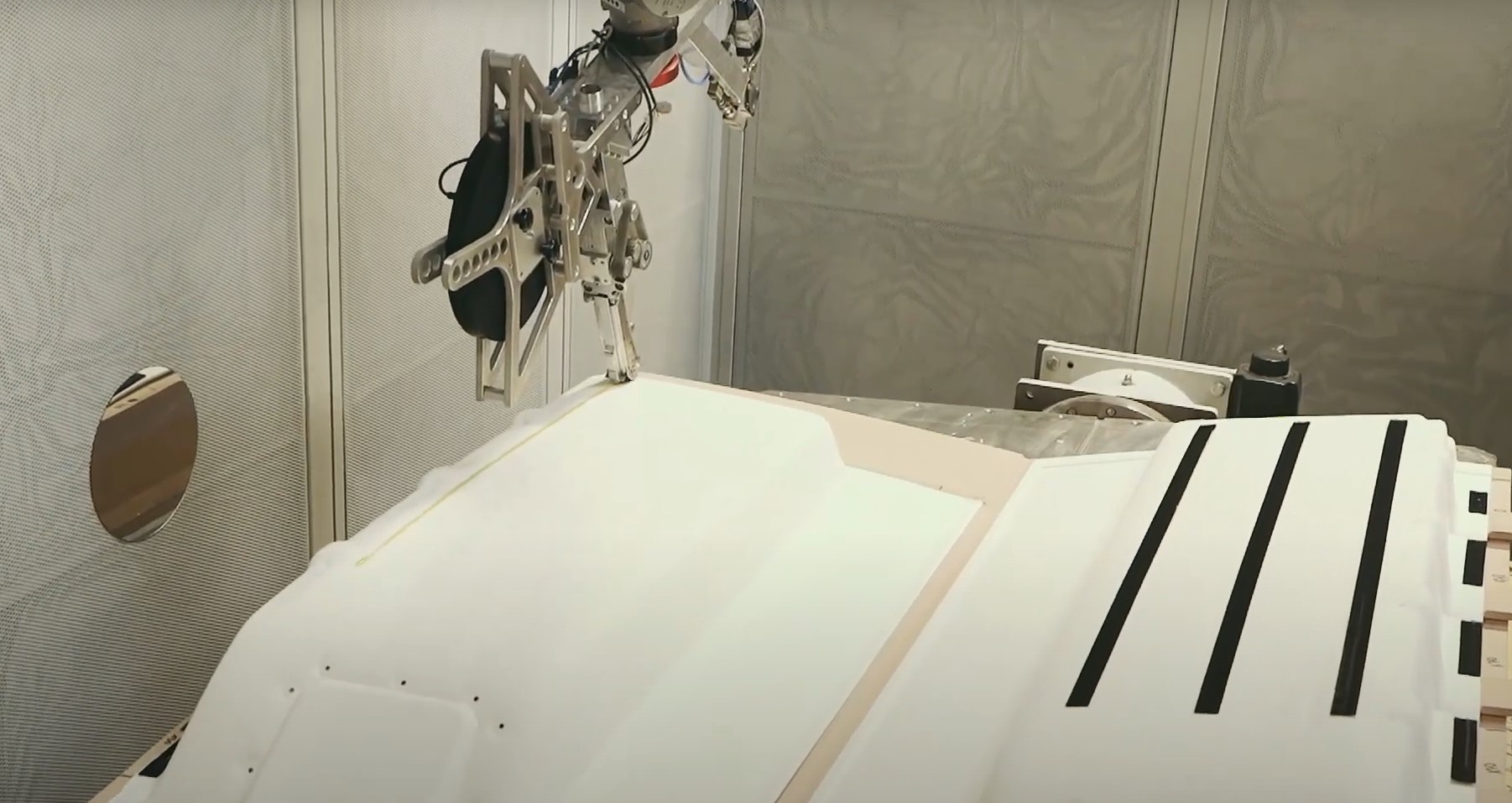

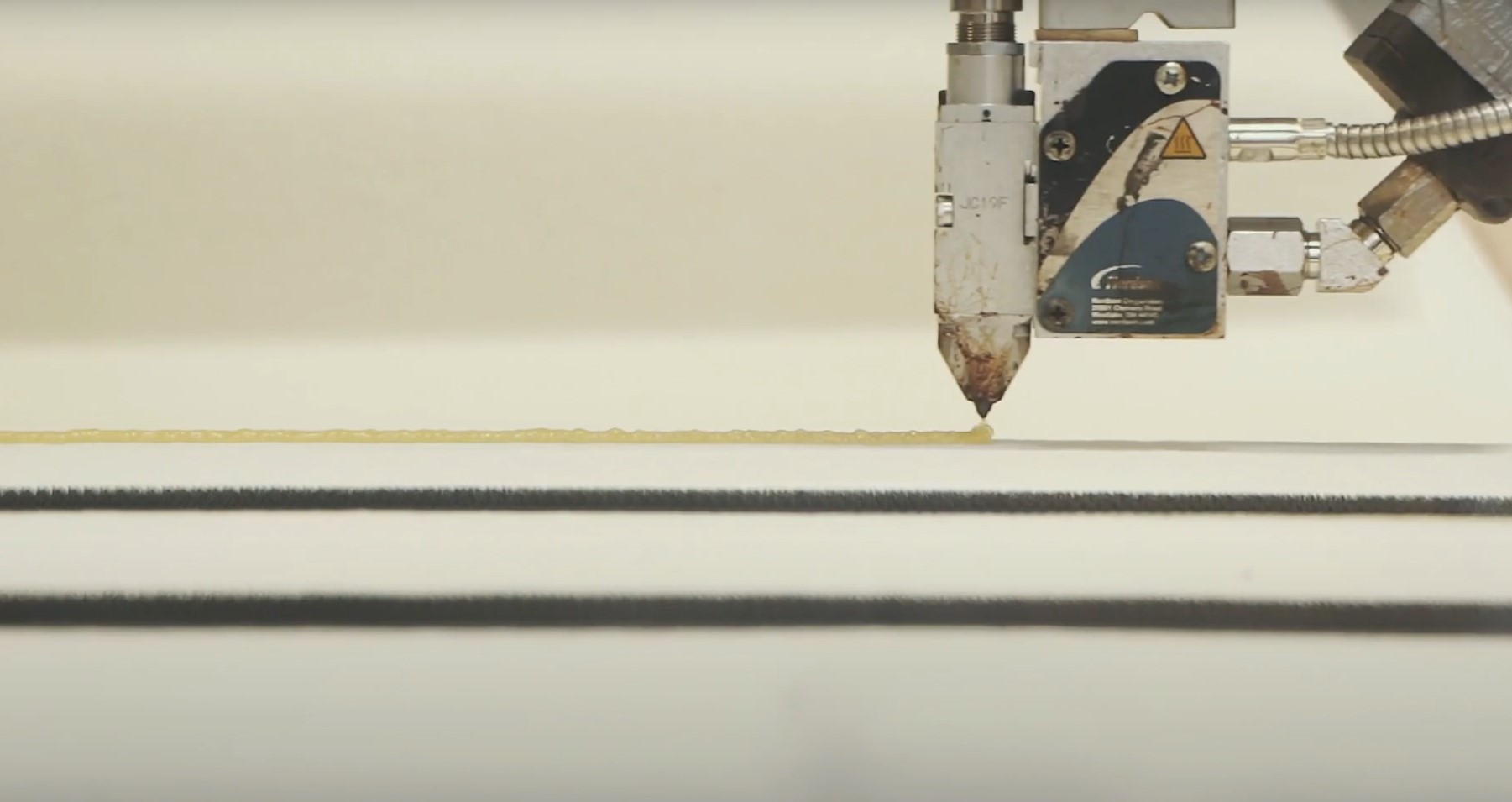

In a high-precision manufacturing application, Comau’s NJ-16-3.1 robots are fully integrated into CNC processing cells to automate taping, water-cutting, and welding tasks.

- Native integration via Siemens Sinumerik enables accurate path control and tight synchronization between machine and robot

- Eliminating standalone robot controllers reduces hardware and simplifies support

- Fast retooling and multi-product handling allow shorter cycle times and greater production flexibility

- Full automation ensures consistent weld and cut quality—even for complex geometries and specialized materials

Built on Comau’s proven robotic platform, the system delivers high efficiency, reliability, and scalability—ideal for both large manufacturers and SMEs.

From cutting and sealing to precision welding, Comau’s robotics enable:

- Full automation within a single control environment

- Real-time CNC-level path control

- Simplified system architecture

- Flexible product management and quick changeovers

How the Comau CNC Robotic Solution Works

Why Choose Comau for

CNC Integration?

A Global Leader in Robotic Automation

With over 50 years of innovation, Comau delivers scalable, high-performance robotic solutions for CNC-driven applications in cutting, welding, and sealing—across industries.

Robots Built for CNC Precision and Speed

The Comau NJ-16-3.1 robot offers tight path control, high-speed motion, and exceptional repeatability. Its compact design fits seamlessly into integrated CNC systems.

Native Integration with Siemens Sinumerik

Comau robots work directly with Siemens CNC via RunMyRobot/DIRECT, enabling single-interface control of both robot and machine. The result: faster response, less complexity, and fewer failure points.

Custom Automation to Fit Your Process

Comau designs automation that fits your exact production needs—from cell layout to material type, product variety, and available floor space—ensuring long-term value and adaptability.

About the System Integrator

Founded in 2020, Maucher CNC Robotic GmbH evolved from a successful partnership between Maucher Formenbau GmbH & Co. KG and bbs-Beteiligungs GmbH.

Specializing in CNC robots and modular CNC-R processing machines, Maucher offers turnkey automation solutions for both large enterprises and small to mid-sized companies. Based in Friedrichshafen, Maucher CNC-R systems are designed for flexibility, high quality, and ease of integration, supporting the digital transformation of modern manufacturing.

For more information, please visit: https://www.maucher-cnc-robotic.de/