Smart, Safe, and Flexible Human-Robot Collaboration

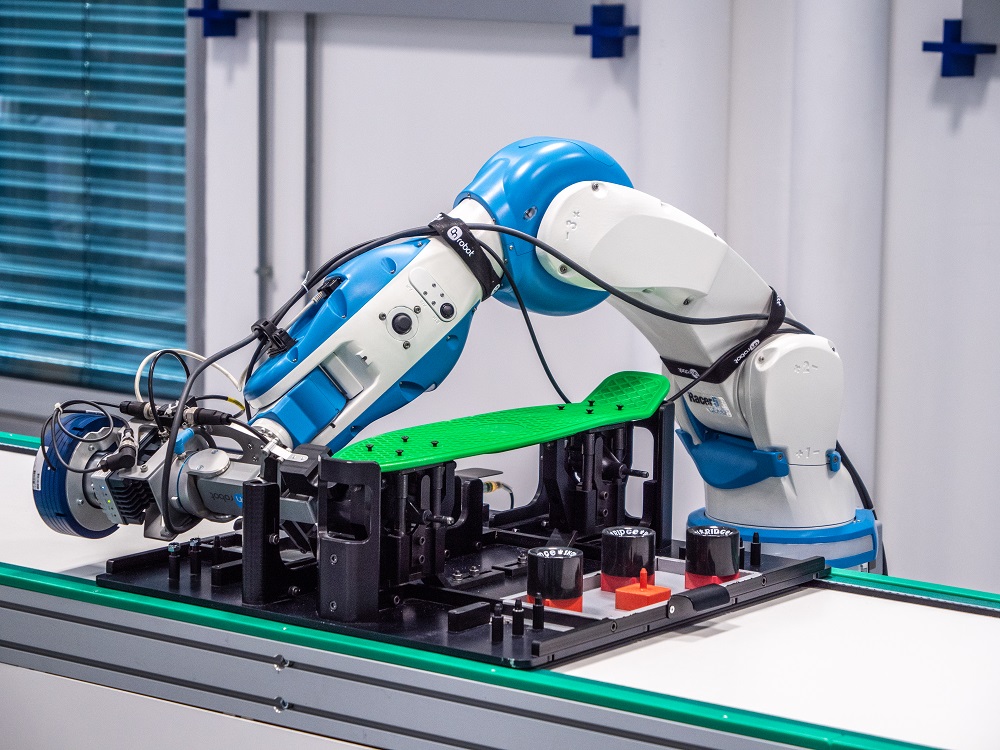

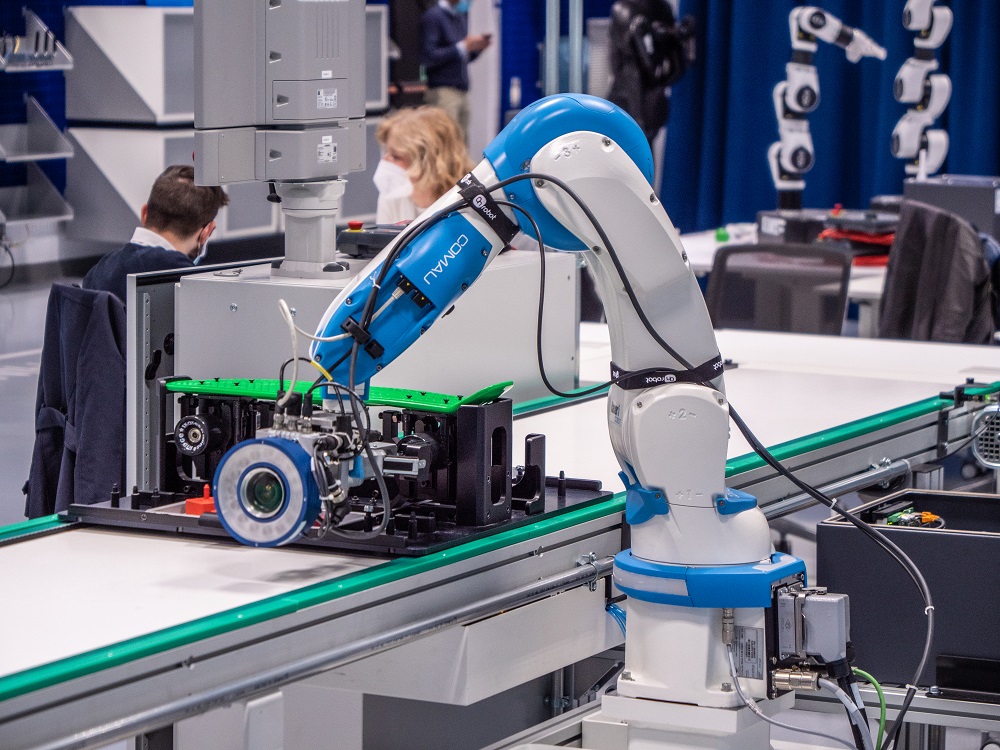

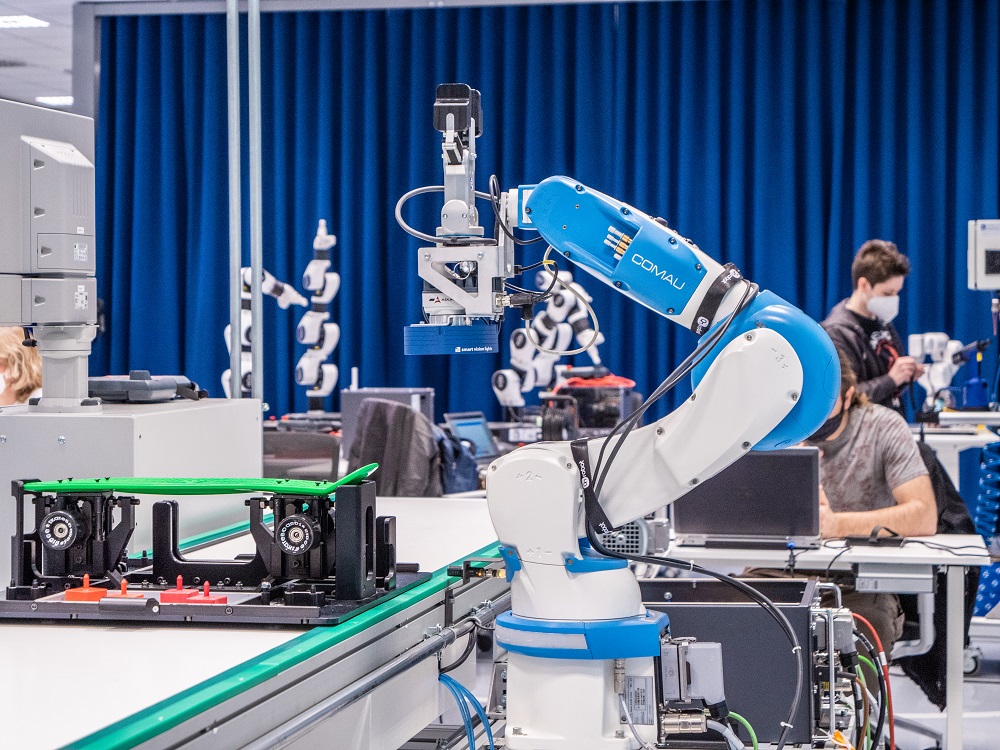

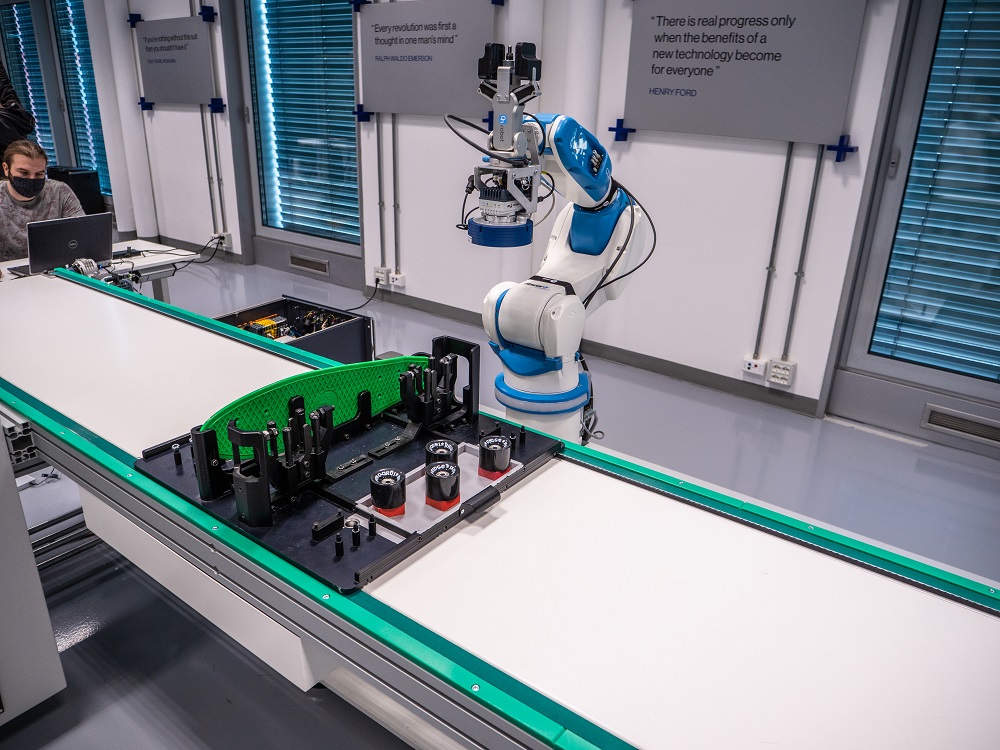

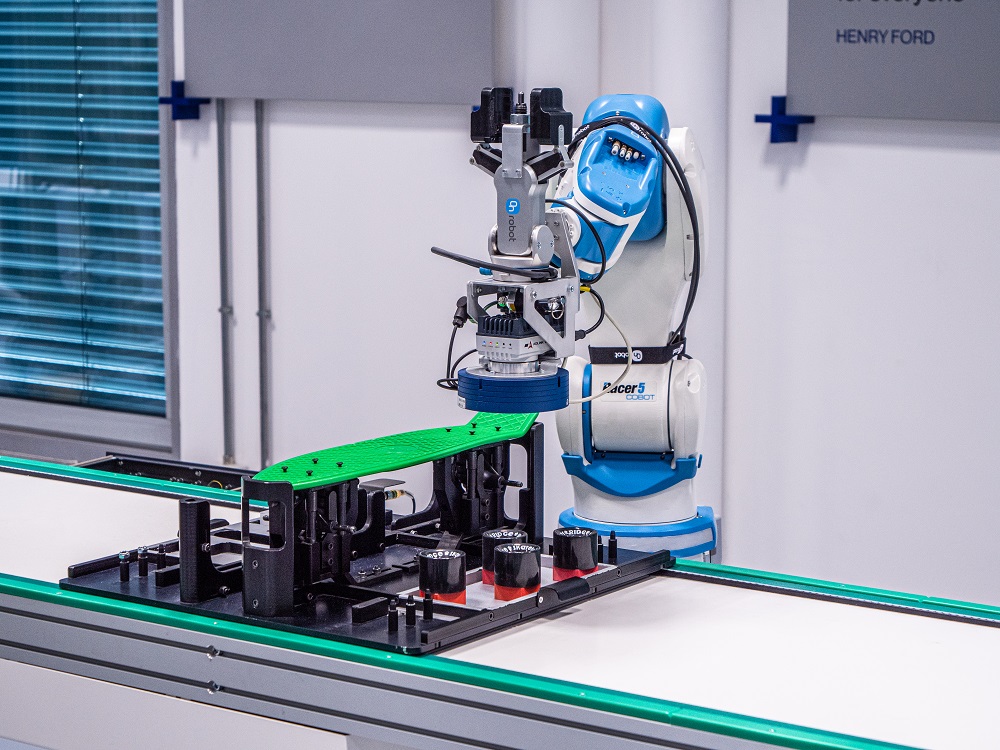

Comau’s Racer-5 COBOT is a collaborative robot designed to combine the speed and accuracy of an industrial robot with the safety features required for direct human interaction. In this demo assembly application, developed for a digital manufacturing environment, the Comau COBOT demonstrates how automation and operator collaboration can safely coexist in a flexible assembly cell.

The application delivers:

This solution provides an ideal example of how Comau’s collaborative robotics support flexible production, operator safety, and real-world assembly applications.

Collaborative Robotics in Action

This video demonstrates the Comau Racer-5 COBOT operating within a demo assembly station, performing a partially automated task involving the handling of small mechanical components.

Case Study: Flexible Human-Robot Collaboration with Comau COBOT

At a fully connected digital station, Comau’s Racer-5 COBOT performs a simulated product assembly process:

- In industrial mode, the robot identifies and picks parts using vision-guided AI

- It places components on the workbench with high-speed precision

- When human input is required—such as handling small screws—the robot switches to collaborative mode, pausing to allow operator intervention

- No barriers or fences are needed, thanks to built-in safety-certified features

Equipped with vision and artificial intelligence, the robot identifies parts on the process pallet, positions them for assembly, and waits in collaborative mode when human intervention is required.

This setup demonstrates how Comau’s collaborative solutions can be used in real industrial environments to increase flexibility and reduce cycle times without compromising safety.

How the Comau Racer-5 COBOT Solution Works

Why Choose Comau for Collaborative Robotics?

Global Industrial Robotics Leader

Comau combines decades of industrial automation experience with cutting-edge collaborative technology, supporting smart, safe, and scalable solutions for modern factories.

Dual-Mode Flexibility with Racer-5 COBOT

The Racer-5 COBOT delivers industrial performance with collaborative safety, switching modes dynamically based on operator presence and production needs.

Seamless Integration with Digital Manufacturing Systems

The robot can be fully connected to existing OT/IT infrastructures—Profinet, cloud platforms, MES systems—allowing it to operate within real Industry 4.0 environments.

Customizable for Your Assembly Needs

Whether in demo environments or full production, Comau’s collaborative robotics are modular, programmable, and ready to support your evolving assembly processes.

About the System Integrator: CIM

The Competence Centre Manufacturing Industry 4.0 (CIM4.0) aims to provide the strategic and operative support instruments for manufacturing-oriented enterprises toward the digital transformation of industrial processes (from design to production, from R & D to the supply chain, from cybersecurity to the blockchain) accordingly to the Industry 4.0 vision.

CIM4.0 aims to strongly accelerate, at local and national level, the transformation process of a wide portion of Italian production ecosystem; especially SMEs. CIM4.0 propose itself as an integrated reference point for all those activities concerning the push of skills and good practices.