• Comau’s new dry room will enable technological and process validation for lithium-ion and next-generation battery cells manufacturing

• The circa 500m2 hub is intended to become an open lab in support of innovative customer projects, and is also available for universities and associations

• The internally developed moisture-controlled (up to -50° dew point) laboratory further strengthens Comau’s cell manufacturing process expertise in addition to demonstrating its ongoing commitment to enabling a pan-European Battery Value Chain

Share this Press Release

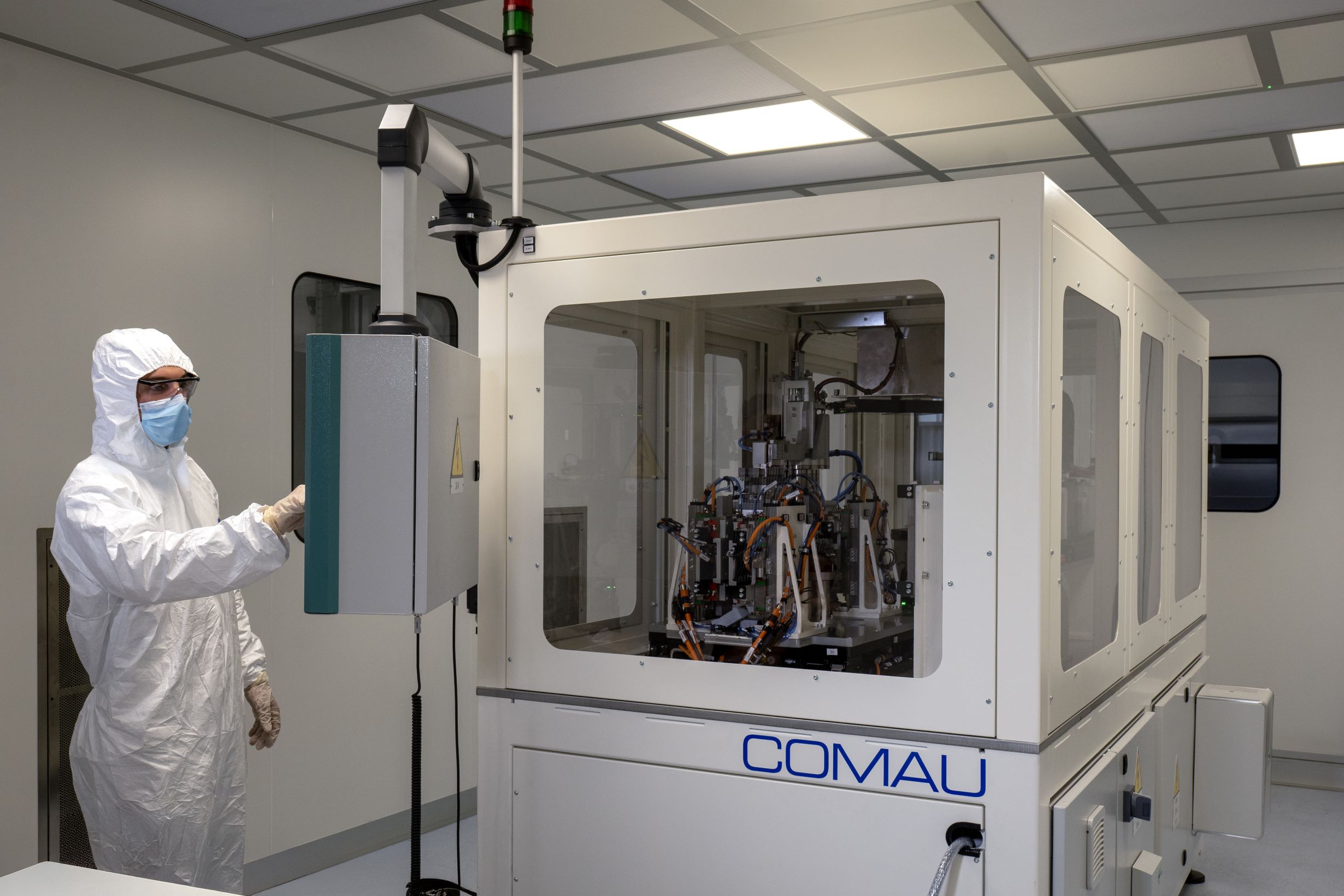

Proprietary, fully-equipped dry room laboratory to develop and test cell manufacturing equipment

Grugliasco (Turin), July 16th, 2025

Comau has built a proprietary, fully-equipped dry room laboratory at its Italian headquarters in Grugliasco to develop and test the cell manufacturing equipment the company has already developed. It will also be used to test new machines targeting Lithium-Ion and Lithium Metal cells, in order to access solid state technologies as a further step towards next-generation and post Lithium batteries.

The fully equipped dry room strengthens the company’s presence in the electrification sector and enhances its end-to-end battery solutions portfolio. It also allows Comau to better support customers as well as validation activities.

The new dry room, for which Comau has invested close to €1 million, aims to facilitate and speed the development and commercialization of new technologies. It features three proto-test spots (2 of which in -40° dew point (DP) and 1 in -50°DP). It will be openly available to customers, universities and associations in addition to Comau’s Global Competence Center team which at present consists of more than 40 engineers. Among the different technologies used for the different processes, the laboratory features Comau’s Racer 5 Sensitive Environments robot.

In terms of processes, the dry room will facilitate Comau’s development in electrode manufacturing, cell assembly and formation aimed primarily to study and validate solutions for solid state and next generation battery production technologies. Moreover the -50 DP room will allow Comau to work with moisture-sensitive materials such as Lithium metal and electrolytes.

Comau’s dry room also is key for the company to proceed with the optimization of ongoing cell assembly developments including notching (both laser and mechanical) and stacking technologies, to name a few.

“As recently demonstrated by the launch of a new full line of Cobots and AMRs, as well as welding technologies, Comau continues to invest in research and development across all of its strategic sectors, including e-Mobility. Our new dry room, which allows us to experiment with new battery cell formats and materials in a controlled, humidity-free environment, reflects our ongoing commitment to advancing industrial innovation while also reinforcing our presence and investments in Italy.”

Pietro Gorlier

Chief Executive Officer at Comau

Comau’s longstanding ability to pioneer new technologies while adapting to different market dynamics is further aided by a network of seven dedicated Innovation and Competence Centers that are strategically located in key markets including Italy, France, China, India and the United States. These global Centers are integral to the company’s ongoing commitment to advancing industrial automation technologies and supporting customers anywhere in the world.

Downloads

About Comau

Comau is a worldwide leader in delivering sustainable advanced automation solutions. With 50+ years of experience and a global presence, Comau is helping companies of all sizes in almost any industry leverage the benefits of automation.

Backed by a continuous commitment to designing and developing innovative and easy to use technologies, its portfolio includes products and systems for vehicle manufacturing, with a strong presence in e-Mobility, as well as advanced robotics and digital solutions to address rapidly growing markets in industrial sectors.

The company’s offering also extends to project management and consultancy. Through the training activities organized by its Academy, Comau is committed to advancing the technical and managerial knowledge necessary to face the challenges related to automation and leverage the opportunities of a constantly changing marketplace.

Headquartered in Turin, Italy, Comau has an international network of 7 innovation centers and 11 manufacturing plants that span 11 countries and employ 3,800+ people. Together with its wide network of distributors and partners, the company is able to respond quickly to the needs of its customers, no matter where they are located throughout the world.

Press Office – Headquarters

| Giuseppe Costabile giuseppe.costabile@comau.com Mob. +39 338 7130885 | Monica Cavaliere monica.cavaliere@comau.com Mob. +39 3386684221 |