Comau NJ Series Powers Innovation in the Foundry Industry

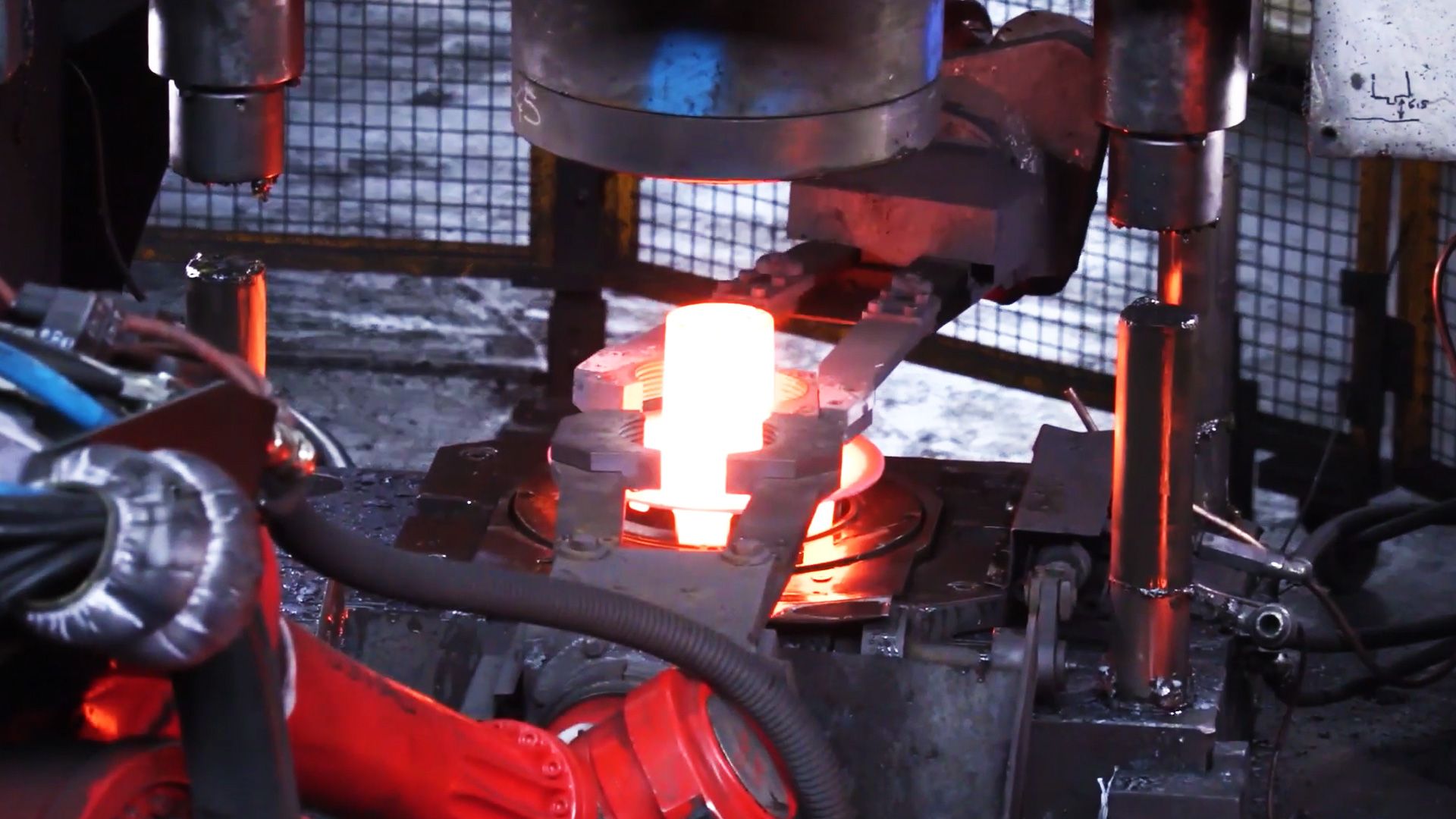

In challenging industrial environments like hot forging, precision and traceability are key.

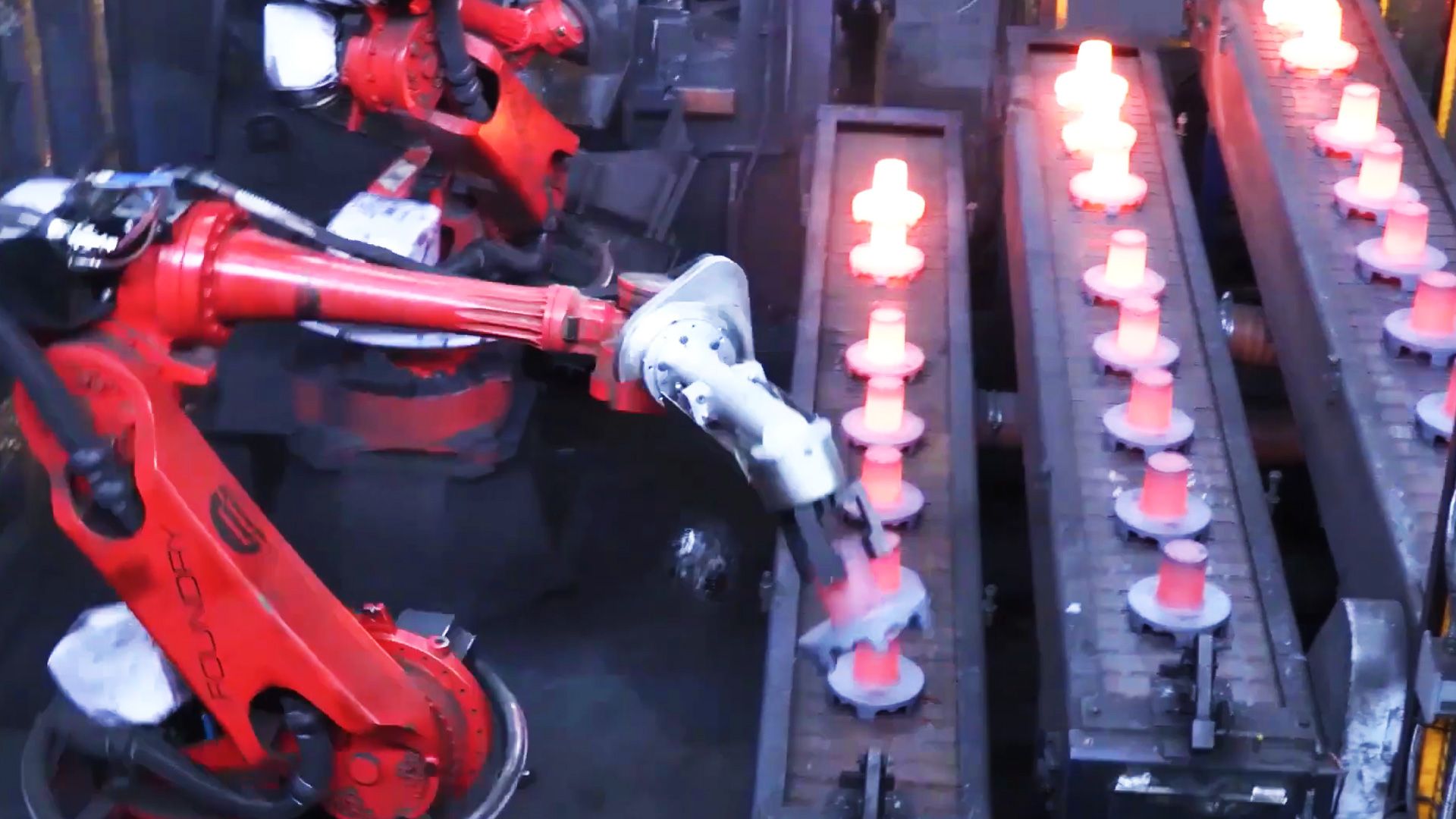

This robotic solution powered by Comau’s NJ articulated robot series enables the full automation of piece handling, visual inspection, labeling, and sorting — right after extraction from the mold.

Combining high-performance robotics with advanced 3D scanning and process control, the system supports the principles of Industry 4.0, ensuring higher quality, reduced manual labor, and enhanced data traceability.

Smart Forging in Challenging Industrial Environments

This video highlights how Comau’s NJ robot enables the automated handling and inspection of forged parts immediately after mold extraction.

Case Study: Advanced Control and Handling with Comau Robotics

To support its evolution toward a smarter, more connected foundry operation, San Grato implemented a semi-automated system centered on the Comau NJ robot. The solution was designed to:

- Automate post-molding handling and positioning

- Perform 3D scanning and defect detection using laser triangulation

- Enable inline control of parts during hot stamping

- Support traceability and process supervision with integrated software

A dedicated 3D scanning system reconstructs the geometry of each component, identifying defects, holes, or imperfections — even in high-heat, high-dust environments.

The integrated solution ensures full product verification, labeling, and sorting, supporting efficient workflows and consistent product quality.

Key system features include:

- Laser-based 3D reconstruction with point cloud comparison

- Process supervision with Co.Mo.Do software for tracking and control

- Seamless integration of manual and robotic operations

- Built for heavy-duty environments, unlike standard measurement systems

This is a scalable solution for manufacturers looking to combine the precision of robotics with advanced inline quality inspection and product traceability—even under extreme conditions.

How the Comau Solution Works

Why Choose Comau for Forging Automation?

Reliable Performance in Harsh Environments

Comau NJ robots are designed for durability and precision—even under heat, dust, and continuous motion typical of forging and foundry applications.

Smart Integration with Quality Control Systems

The robotic system integrates with inline inspection and data acquisition platforms to deliver real-time insights and full traceability.

Flexible, Scalable Architecture

The cell can be adapted to different mold sizes, parts, or inspection criteria, making it future-proof for evolving production needs.

Enhanced Quality & Productivity

Combining automated inspection and sorting reduces human error, speeds up quality control, and improves product consistency.

About the System Integrator: E6POS

E6POS specializes in handling applications and it is particularly active in foundry, machine tending and end-of-line heavy handling. The company has successfully worked in all these sectors with Comau robotics.

As Mr. Baronio E6POS CEO, declared, “Comau is incomparable as far as machine characteristics, service and assistance are concerned. In addition to this, I have to mention the excellent value for the money and the fact that the latest models of robots, including Racer, fully meet our expectations as integrators, as well as those of the companies where we install them.”