Smart Box Assembly and Product Handling with Comau’s Rebel-S Technology

In industries where speed, precision, and traceability are essential, Comau’s Rebel-S SCARA robots offer a smart solution for automated box filling and assembly.

This system, deployed in a pharmaceutical packaging line, uses two Rebel-S robots to automate the placement of product containers, instruction kits, and box closing, reducing cycle time and improving repeatability across multiple box formats.

Comau SCARA Robots in Pharma Packaging

This video demonstrates how Comau’s Rebel-S SCARA robots are integrated within a filling and boxing line, enabling the automatic packaging of pharmaceutical kits—including containers, spoons, dispensers, and instruction leaflets.

Case Study: Flexible Box Assembly with Comau Rebel-S

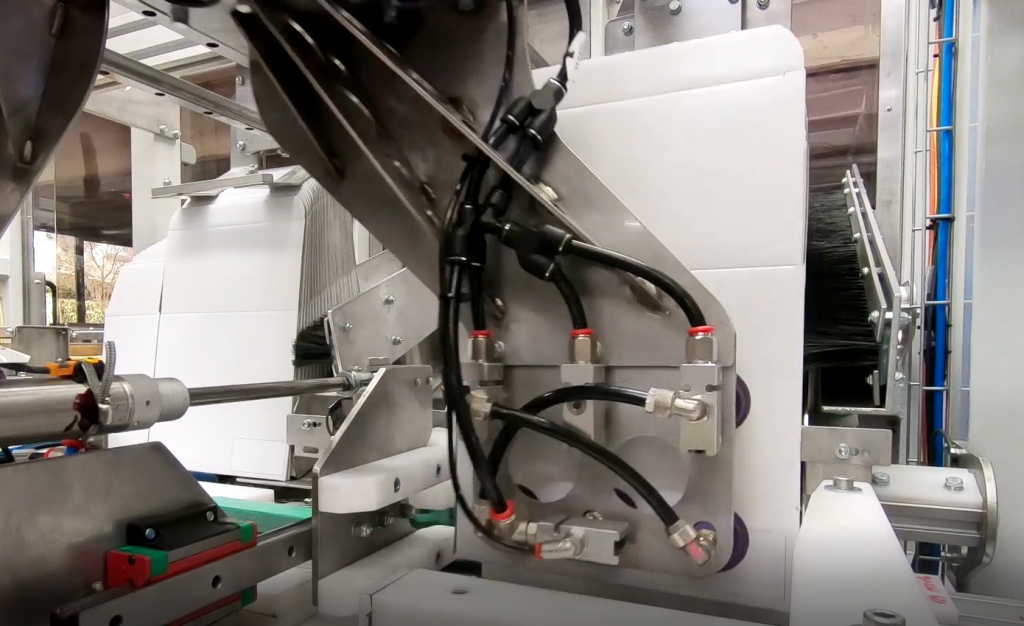

In this pharmaceutical line, two Comau Rebel-S SCARA robots are used for automated box filling and preparation:

- Robot 1 places containers into pre-assembled boxes

- Robot 2 adds kits or instruction booklets on top

- Subsequent stations handle printing, vision inspection, and box closure

The robots operate at the second and third stations of the line, providing fast, precise placement and seamless box handling—all within a controlled, traceable process.

Thanks to their speed, compact size, and flexible mounting options, Rebel-S robots ensure:

- Fast cycle times with minimal manual intervention

- Repeatable and accurate placement even with different packaging formats

- Seamless integration into existing pharma-grade filling lines

How the Comau Rebel-S SCARA Solution Works

Why Choose Comau for Packaging Automation?

Global Industrial Robotics Leader

Comau’s experience in high-precision automation ensures that even the most regulated industries—like pharmaceuticals—benefit from robust and reliable solutions

Compact & Flexible SCARA Robots

The Rebel-S range offers five SCARA models with horizontal reaches from 450 to 750 mm, vertical reach of 200 mm, and payload of up to 6 kg—ideal for fast pick-and-place and packaging tasks.

Easy Integration with Packaging and Inspection Systems

Whether integrated into a full filling line or standalone applications, Comau robots are built to work with your existing equipment, minimizing downtime and maximizing return on investment.

Customizable Automation That Grows With You

Comau’s solutions are built around your needs—modular, scalable, and ready to evolve as your product portfolio or packaging formats change.

About the System Integrator: SISCODATA

Siscodata was established in 1974 and started its activity as terminal and equipment producer for Siemens and Philips, and manufacturer of sets for nuclear physics and aeronautical electronic systems.

From 1978 onwards, it has developed systems for the textile field, growing at first in the domestic market and afterwards in the international arena, with plants sold and installed all over the world.

The company, which is located in the north of Italy about 50 kilometers from Milan, produces customized systems for many automation requirements and is organized in the following divisions: Research and Development, Software and Electronics, Mechanics, Engineering, and Consulting.