Enhancing Flexibility and Process Control in Welding Operations

Modern metalworking demands flexibility, precision, and complete process control. With Comau’s advanced robotic technology at the core, manufacturers can implement fully customized welding cells tailored to their production needs – capable of handling both small parts and large structural components with maximum efficiency.

Comau’s robotic welding solutions combine high-performance automation with adaptability, ensuring consistent weld quality, reduced cycle times, and seamless integration into existing production lines.

High precision Robotic Welding in Action

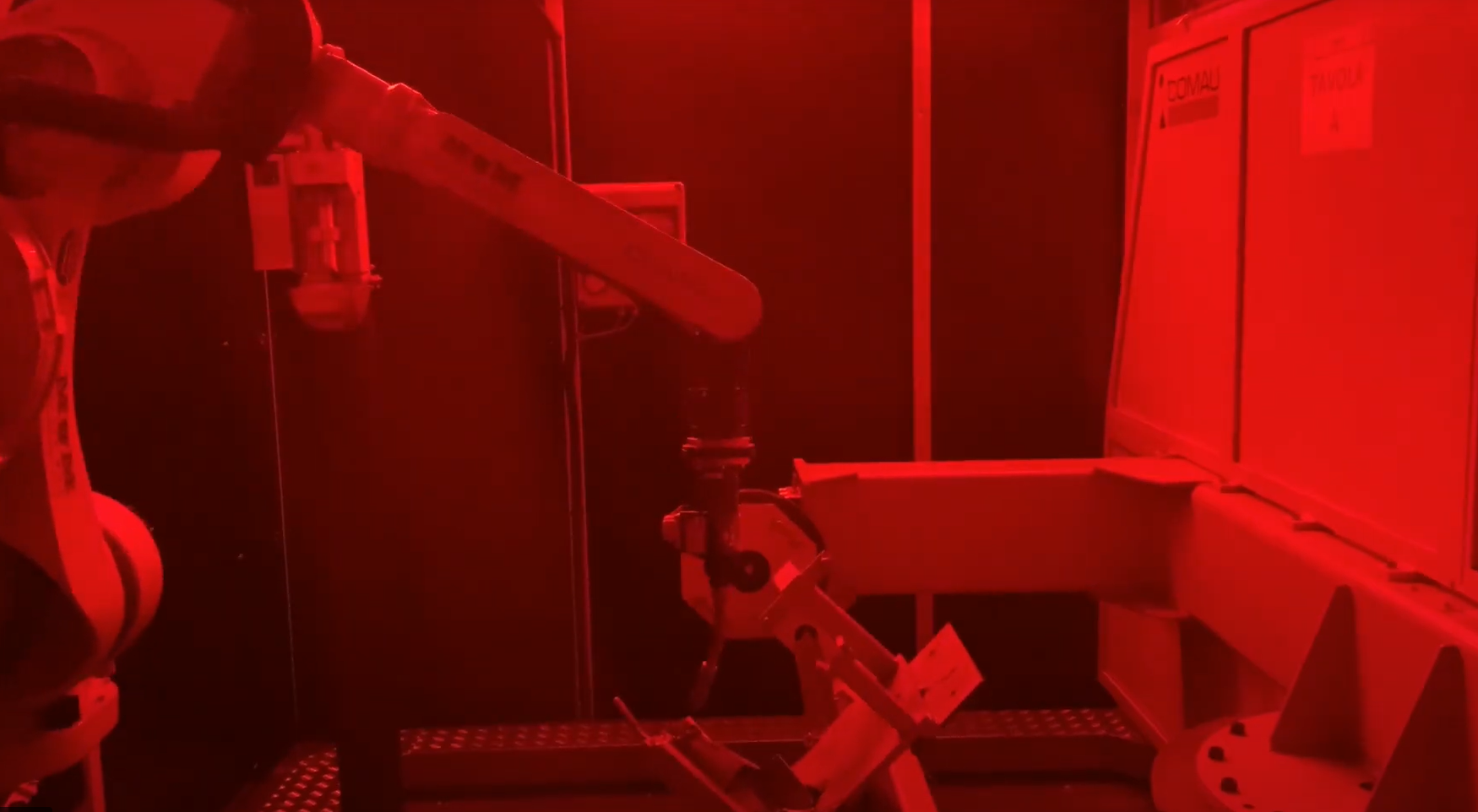

This video demonstrates a fully automated robotic welding solution featuring Comau robots in a multi-cell configuration.

Case Study: Flexible Welding Automation with Comau Robotics

AAt a major metal fabrication plant, Comau deployed a customized robotic welding system built to support a wide variety of part sizes and shapes—within a single, flexible work cell.

- Comau robots and positioners deliver precise, multi-axis movement and part access

- The entire system is CE-certified, ensuring maximum operator and machine safety

- Industry 4.0-ready software provides real-time diagnostics, teleassistance, and predictive maintenance

- The fully automated workflow—from part loading to unloading—minimizes manual handling and ensures repeatable, high-quality welds

Built around Comau’s robust robotic platform, the system guarantees long-term performance, easy reconfiguration, and scalability for future production needs.

Designed for versatility, the system handles everything from precision welds on small parts to multi-sided operations on larger components, while supporting full Industry 4.0 integration, remote monitoring, and predictive maintenance.

How the Comau Robotic Welding Solution Works

Why Choose Comau for Welding Automation?

A Global Leader in Industrial Automation

With more than five decades of experience, Comau is trusted worldwide for delivering automation systems that drive productivity and ensure consistent process quality—especially in complex, high-precision industries like metalworking.

Robotic Technology Built for Performance

Comau robots are engineered to manage high-speed welding paths, variable part sizes, and multi-material handling—while maintaining strict tolerances and enabling complete process traceability.

Flexible Configurations to Match Any Production Need

From small-batch production to continuous, high-volume workflows, Comau offers tailored automation that evolves with your business. Whether using a single robot or a synchronized multi-robot cell, your system is built to scale.

Seamless Integration into Your Production Line

Comau ensures that every robotic welding solution integrates effortlessly into your line—supporting layout constraints, operator workflow, and real-time data sharing across your digital infrastructure.

About the System Integrator: MGM Robotics

Founded in 2020, MGM Robotics specializes in custom robotic systems for automated manufacturing and welding applications across multiple industries.

From feasibility analysis to installation, training, and global support, MGM delivers turnkey automation solutions tailored to the unique requirements of each customer. By combining cutting-edge robotics with in-house engineering expertise, MGM helps companies streamline production, enhance quality, and improve competitiveness.