- Comau brought its fully automated hairpin and minipin stator manufacturing technologies at CWIEME Shanghai, reinforcing its leadership in scalable, high-efficiency e-motor production

- With flexible, end-to-end solutions covering wire forming through laser welding, Comau empowers OEMs and tier 1s to streamline multi-variant e-mobility manufacturing with precision and speed

- The company’s advanced electric drive system assembly capabilities highlight its strategic commitment to innovation and sustainable mobility across the entire e-drive value chain.

Shanghai, June 25, 2025

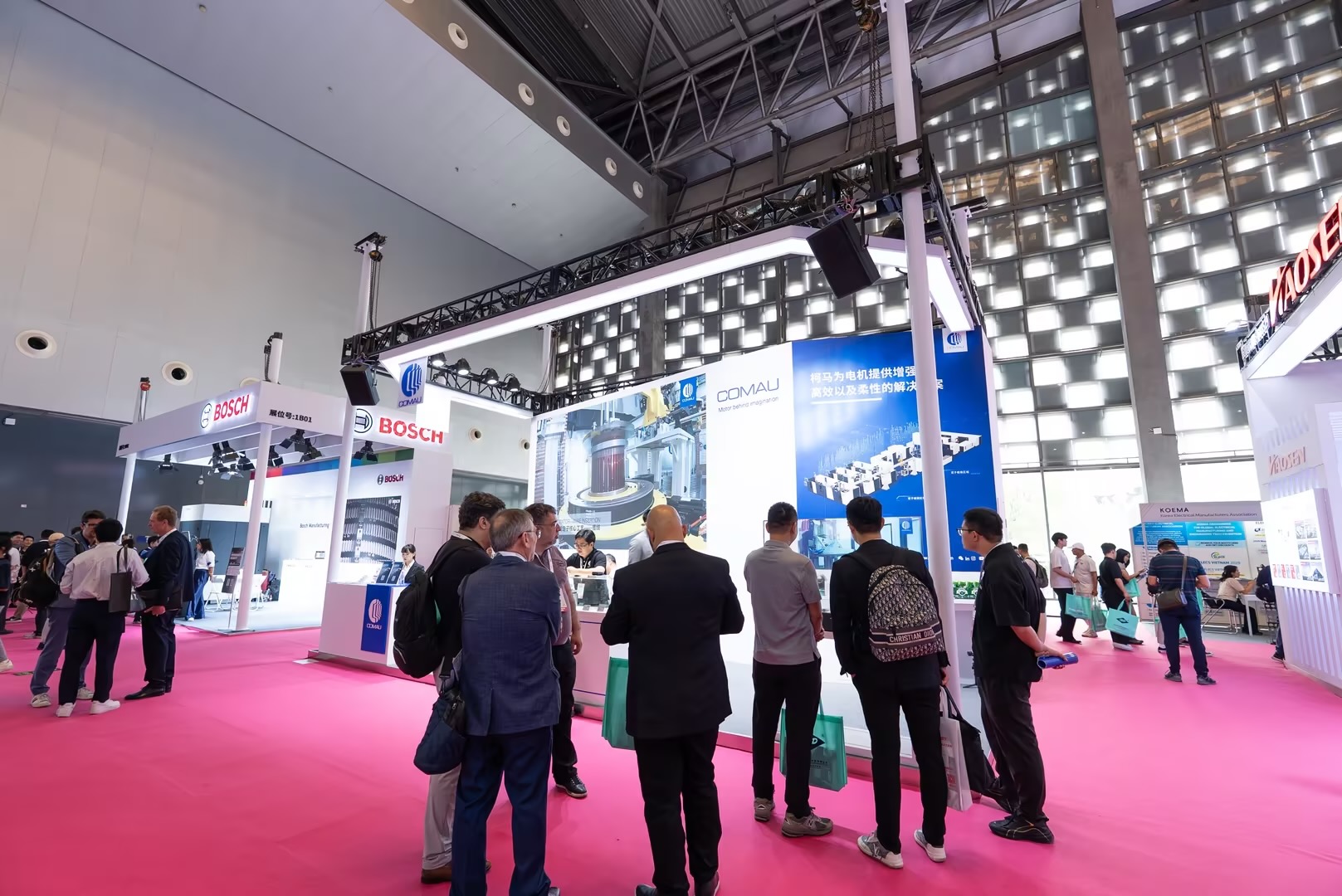

Comau exhibited at CWIEME Shanghai 2025 (June 25-27), one of Asia’s premier trade fairs for coil winding, electric motors, and transformer manufacturing. At the 10th anniversary edition of the event, held at the Shanghai World Expo Exhibition & Convention Center, Comau showcased its latest advancements in fully automated stator manufacturing and electric drive system (EDS) assembly, designed to help OEMs and Tier 1 suppliers improve flexibility, maximize efficiency, and accelerate time-to-market in electrification.

At Booth 1B07, visitors could explore Comau’s comprehensive portfolio of hairpin and minipin stator manufacturing solutions, critical technologies that directly influence e-motor performance. Drawing on its long-standing expertise in e-mobility, Comau presented a fully automated stator production line that covers every key stage of the process: wire forming, insertion, widening, twisting, cutting, and laser welding. The system is engineered for precision, consistency, and scalability, even in high-throughput production environments.

Comau’s modular hairpin stator solution is easily reconfigurable — from semi-automated to fully automated setups — to support diverse production needs, covering from low volume lines to mass production lines. The system has also been enhanced to support minipin stators, a compact evolution of traditional hairpins. With shorter pin ends, minipin stators enable greater power density and improved space utilization, aligning with the growing demand for smaller, high-performance e-motors in China.

In addition to stator production, Comau also presented its end-to-end e-drive system assembly solutions, ranging from final EDS main line assembly to sub-system assemblies of e-motor, rotor, e-transmission and e-controllers. These technologies support multi-variant production with high precision and traceability, addressing key customer challenges across the electrification value chain. Comau’s integrated portfolio reflects its strategic commitment to local innovation, scalable automation, and sustainable industrial transformation in the APAC region.

With more than 50 years of experience in industrial automation, Comau offers a cutting-edge portfolio of products and technologies covering the entire electrification value chain. Besides solutions related to the e-drive value chain, Comau also offers solutions for the production, assembly, testing and recycling of batteries and BESS (Battery Energy Storage Systems), from the laboratory and pre-production stage to mass production. Comau’s offerings extend to all levels of scale, from cell manufacturing to pack and tray assembly to end-of-line testing and end-of-life treatment solutions.

As electrification continues to reshape the global mobility landscape, Comau reinforces its role as a trusted partner in driving technical excellence and operational agility for its customer.