Optimize Material Handling and Intralogistics: discover Comau’s MyMR Autonomous Mobile Robots

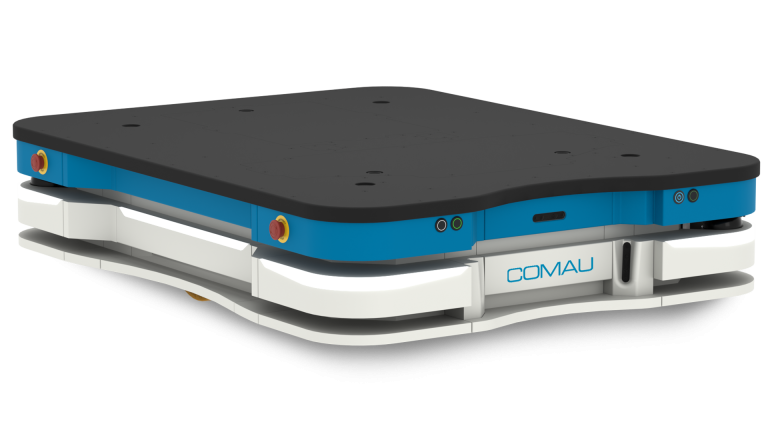

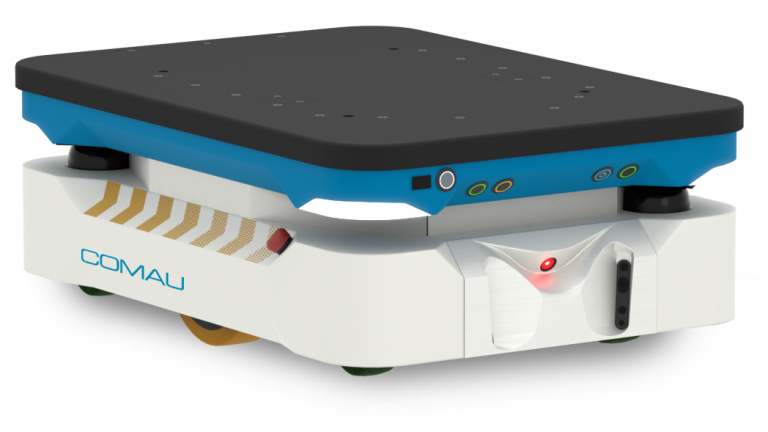

Designed to operate without fixed infrastructure such as magnetic tapes or floor markings, MyMR ensures seamless adaptability to changing layouts and dynamic workflows. The portfolio includes three AMR models, MyMR-300, MyMR-500, and MyMR-1500, each tailored to different payload requirements, covering a wide range of use cases, from production line supply and kitting to warehouse automation.

Equipped with advanced navigation, real-time obstacle avoidance, and intelligent fleet management, MyMR can safely and efficiently move across the facility, even in high-traffic or shared spaces. The robots also offer native integration capabilities for line and system coordination, enhancing productivity and reducing downtime.

Quick deployment, low integration complexity, and reduced operational overhead with Autonomous Mobile Robots

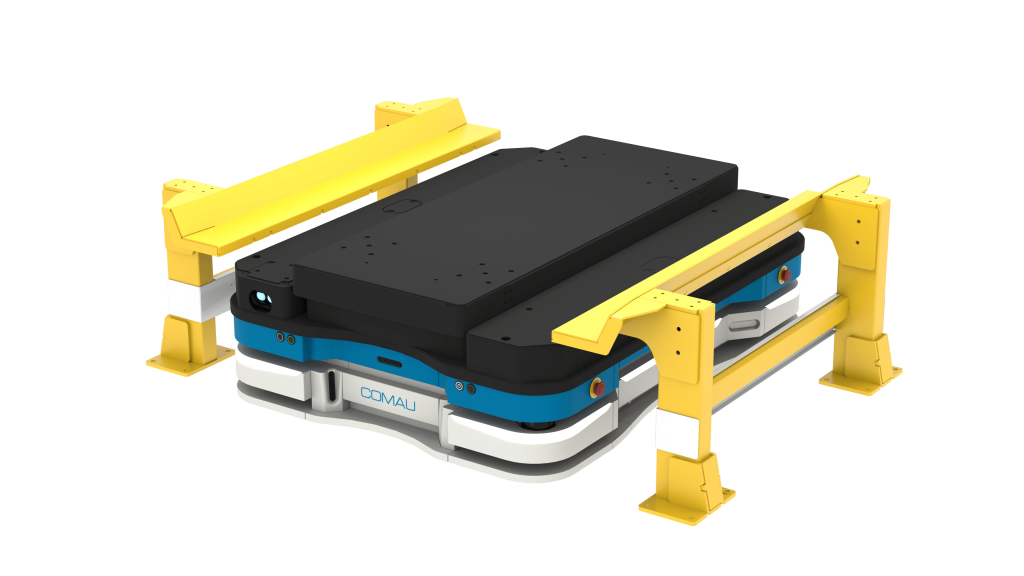

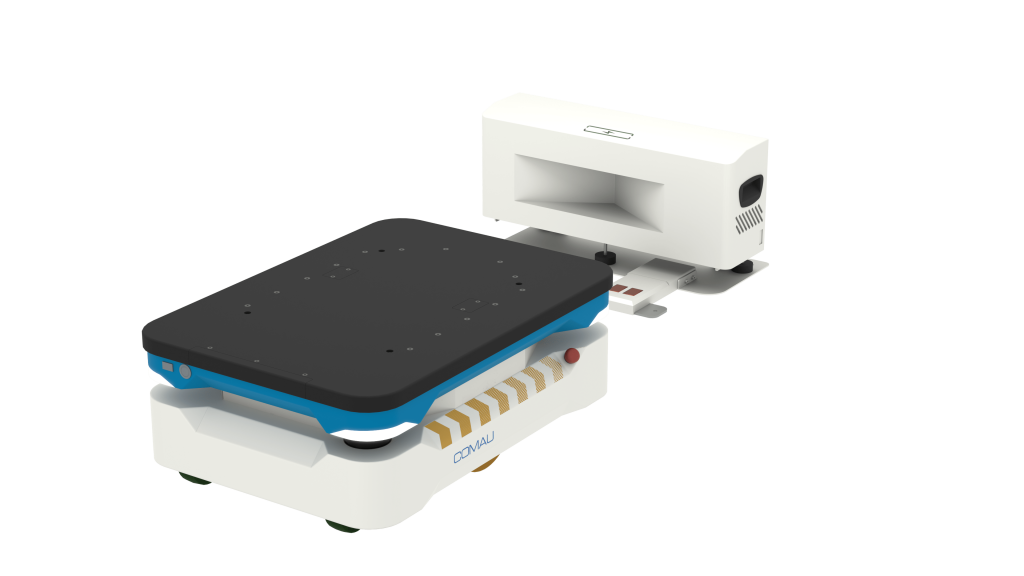

To extend their functionality, Comau provides a range of standard attachments including lifters and conveyors. Additionally, thanks to their software-driven architecture, MyMR units can be easily reconfigured from AMR to Automated Guided Vehicle (AGV) mode, allowing companies to adapt their operations over time.

With quick deployment, low integration complexity, and reduced operational overhead, MyMR ensures a fast return on investment, making it a strategic and future-ready choice for warehouse and intralogistics automation.

Optimize material handling with scalable and flexible automation

Discover Comau’s Autonomous Mobile Robot Family. A comprehensive solution designed for manufacturers and logistics providers

MyMR: Real Benefits for Smart Transportation

Fleet Management System

MyMRs navigate freely throughout the facility, enabling workflow optimization through dynamic task allocation. Robot selection is based on key parameters such as current jobs, distance to destination, battery level, and workload distribution—helping to prevent bottlenecks and increase overall throughput. All AMRs are centrally managed and monitored via the MyMR Fleet Manager, a web-based interface accessible from smartphones, tablets, or computers connected to the internal Wi-Fi network.

Fast Deployment

MyMR can be fully operational within a few hours by simply mapping the facility—this is done by manually guiding the robot through the environment, setting destination points as stations, and defining workflows. No advanced training is required, making deployment fast, simple, and user-friendly.

No Infrastructure Nedeed

Unlike traditional mobile robots, MyMR do not require any fixed infrastructure such as magnetic tapes, lines, or reflectors. Using onboard sensors, it creates a 2D map of the facility and navigate freely—wherever people can go, MyMR can go. As a result, common causes of stoppages, such as damaged tapes or blocked reflectors, are eliminated. This not only reduces initial deployment costs but also eliminates ongoing maintenance expenses related to guiding infrastructure, ensuring more reliable and flexible operations.

Safety

Equipped with integrated 2D laser scanners and additional sensors such as 3D cameras, MyMR offers advanced environmental awareness, it can detect people and moving objects—such as forklifts and pallet trucks—and dynamically adjusts its speed and path to ensure safe and efficient navigation.

Fast ROI

MyMRs offer a strong return on investment (ROI) by significantly reducing labor costs, lowering the need for fixed infrastructure, and minimizing downtime through intelligent navigation and task automation. With an entire family of AMRs available—each designed to handle different payloads and use cases—businesses can scale their automation strategy with maximum flexibility. Their ability to optimize workflows, adapt to evolving production needs, and operate continuously leads to increased throughput and long-term cost savings, making them a smart investment for modern intralogistics

MyMR Fleet Manager

Seamless control and supervision of your AMR fleet from any smart device.

Applications Covered with Autonomous Mobile Robots

AMRs are a smart choice for manufacturers and logistics providers looking for flexible and scalable automation, to optimize material handling and intralogistics, without the constraints of fixed infrastructure for evolving layouts and dynamic workflows.

Intralogistics

Material transport across production and warehouse areas

Warehouse Automation

Goods receiving, storage, and outbound logistics

Production Line Supply

Automated delivery to assembly and testing stations

Kitting and Sequencing

Efficient handling of part kits to support production flow

Are you ready to discover how Comau’s Autonomous Mobile Robots can elevate production line efficiency?

Do you need

more information?

Would you like to have a customized solution?

MyMR Family Technical Specifications

| Model | Max Payload | Weight | Drive Configuration | Max Speed | Turning Radius | Position Accuracy | Operating Enviroment | Battery | Charge Time | Nominal Run Time | Navigation System |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MyMR-300 | 300kg | 130kg | Differential | 2m/s | Turn in place ability 475 mm sweep area radius | +/- 1cm, +/- 1deg | Indoor | Li-Ion | 2 hrs for %0 to %80 | 10 hrs | Natural Navigation |

| MyMR-500 | 500kg | 190kg | Differential | 1.5m/s | Turn in place ability 860 mm sweep area radius | +/- 1cm, +/- 1deg | Indoor | Li-Ion | 2 hrs for %0 to %80 | 8 hrs | Natural Navigation |

| MyMR-1500 | 1500kg | 265kg | Differential | 1.5m/s | Turn in place ability 837 mm sweep area radius | +/- 1cm, +/- 1deg | Indoor | Li-Ion | 2 hrs for %0 to %80 | 14 hrs | Natural Navigation |

MyMR Attachments

AMR standard attachments such as a lifter or conveyor enable every possibile use case for warehouse automation and interlogistics.