Precision-Driven Robotics for Advanced Manufacturing

Manufacturing operations hinge on precision. In industrial environments that demand the highest accuracy standards, even the smallest measurement matter. Without exact robot positioning, industries can face a cascade of impacts, including prolonged production cycles, slower time-to-market, compromised product quality, or increased material waste.

The ability to achieve and maintain precise robotic movements is paramount for optimizing efficiency, ensuring consistent output, and driving innovation in advanced manufacturing processes.

Maximize Robot Positioning and Processing Precision for Continuous Operations

Comau High Accuracy is an advanced software toolkit engineered to maximize the precision of industrial robots movements in complex 6 Degrees of Freedom (6DoF) applications, including high-end material processing, deposition, and finishing.

By combining two intelligent correction strategies, the High Accuracy toolkit dramatically enhances the robot’s ability to follow predefined paths with exceptional precision, ensuring superior performance in demanding industrial environments.

How it Works

Precise motion without the need for manual programming

The High Accuracy software optimizes robot position and speed targets using path data or real-world robot measurements. It processes G-code files, creating optimized versions for robot execution, streamlining the workflow from simulation to production.

Maximum positioning accuracy

Thanks to high-precision external measurement systems like laser trackers, our solution ensures unmatched robotic accuracy. Positioning errors are automatically detected and corrected guaranteeing precise trajectory execution within the the measured volume up to 0.2 mm accuracy.

Smooth and precise movements

The optimization module analyzes G-code, assigning suitable robot speeds based on tool path geometry. This avoids sudden accelerations, improves path adherence, and ensures smoother, continuous motion, which is particularly beneficial for complex CAD-generated paths.

Transform your operations

with the power of precise robotics

- Streamlined workflow from simulation to production

- Single on-site calibration unlocks high-precision, reliable performance

- Works offline via a dedicated APP

- Compatible with both trajectories and single points

- Offline optimization within 3D Printing or Processing APP

- Available for high-payload robots, such as the Comau N220 (220 kg), ideal for applications requiring strength, stiffness, and large-scale precision

Ready to elevate robotic precision levels?

Book a demonstration

High Accuracy APP

Pinpoint accuracy of up to 0.2mm

The High Accuracy APP is designed to elevate robot performance by automatically compensating for robot position inaccuracies. Its core function is to improve 3DoF and 6DoF precision, enabling accuracies up to 0.2 mm.

As an efficient offline tool, the App guides users through the complete compensation workflow, from data collection and optimized execution. This ensures reliable outcomes without the necessity for manual corrections.

With the High Accuracy APP, you can:

Automatically compute robot compensation on user points, usable within the app or exported to other environments

Effortlessly apply compensation to any set of user-defined target points

Whether your focus is advanced processing, aerospace, or high-accuracy manufacturing, the High Accuracy APP simplifies precision, allowing you to concentrate on performance.

Applications

- 3D Printing,

- Material Processing

- Precision Assembly

- Sealing/Gluing

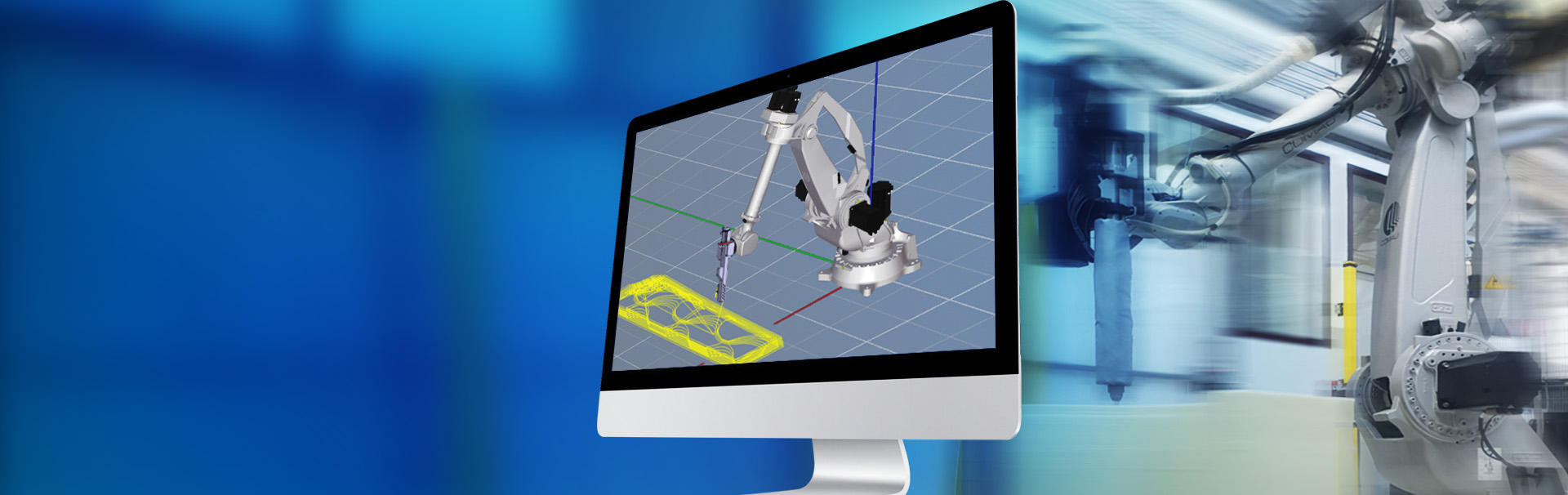

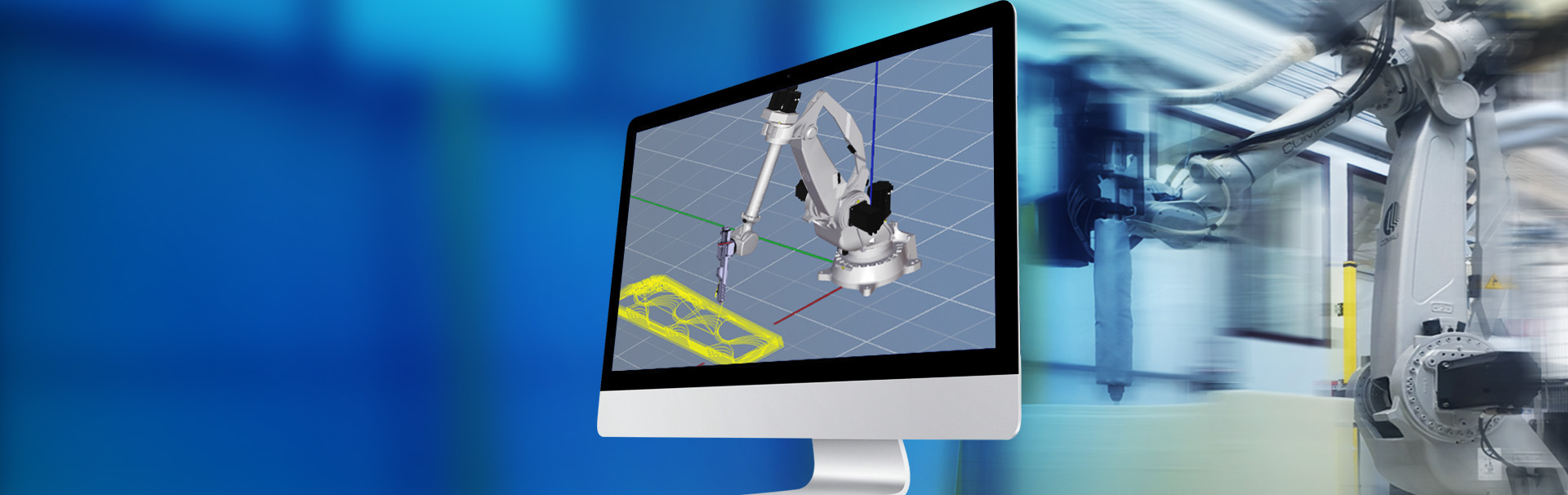

3D Printing APP

From CAD to Robotic Printing in Just a Few Clicks

Comau’s 3D Printing APP integrates both maximum positioning accuracy and smooth and precise movements to produce precise 3D prints directly from G-code files. It supports extruder control as an additional robot axis and generates binary files ready to run on robot controllers, eliminating the need for custom code.

Features

- Direct execution from G-Code to robot, no programming required for the end user

- Improved robot motion for accurate path following and high-quality products

- Robot simulation to detect potential issues before real-world implementation, saving time and materials

- Automatic extruder management

- Intuitive graphical interface in RoboShop

- Suitable for any 3DoF printing task

Processing APP

Advanced 6DoF Control for Peak Performance

The Processing App enables milling operations with full 6 degrees of freedom. It adopts the same advanced logic for compensation and optimization as the High Accuracy toolkit and includes a G-code parser specifically tailored for processing needs.

Features

- Direct execution from G-Code to robot, no programming required for the end user

- Improved robot motion for accurate path following and high-quality products

- Robot simulation to detect potential issues before real-world implementation, saving time and materials

- Intuitive graphical interface in RoboShop

- Suitable for any 6DoF processing task

Why Choose Comau High Accuracy?

Choosing Comau High Accuracy means investing in unparalleled precision and efficiency for your robotic processes. Our software offers:

- Higher precision in robotic processes

- No robot programming required

- User-friendly, fully offline software

- Expandable to various industrial applications, including dispensing, laser cutting, 3D printing, and small parts assembly