High-Precision Path Control with Comau and Siemens Sinumerik

In advanced manufacturing, achieving accurate machining on complex 3D surfaces requires maximum control and synchronization between systems.

Comau meets this challenge with a automated milling solution that leverages direct integration with Siemens Sinumerik—eliminating the need for a separate robot controller.

This integrated automation setup boosts both productivity and precision, making it ideal for industrial applications that combine milling and robotics within a single, unified control environment.

Precision Milling with Comau and CNC Integration

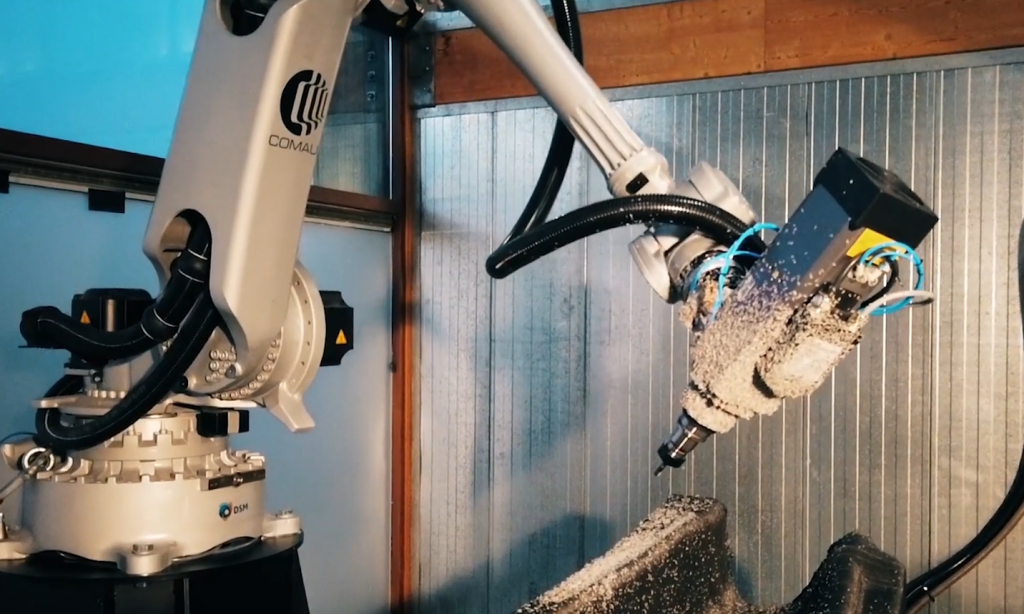

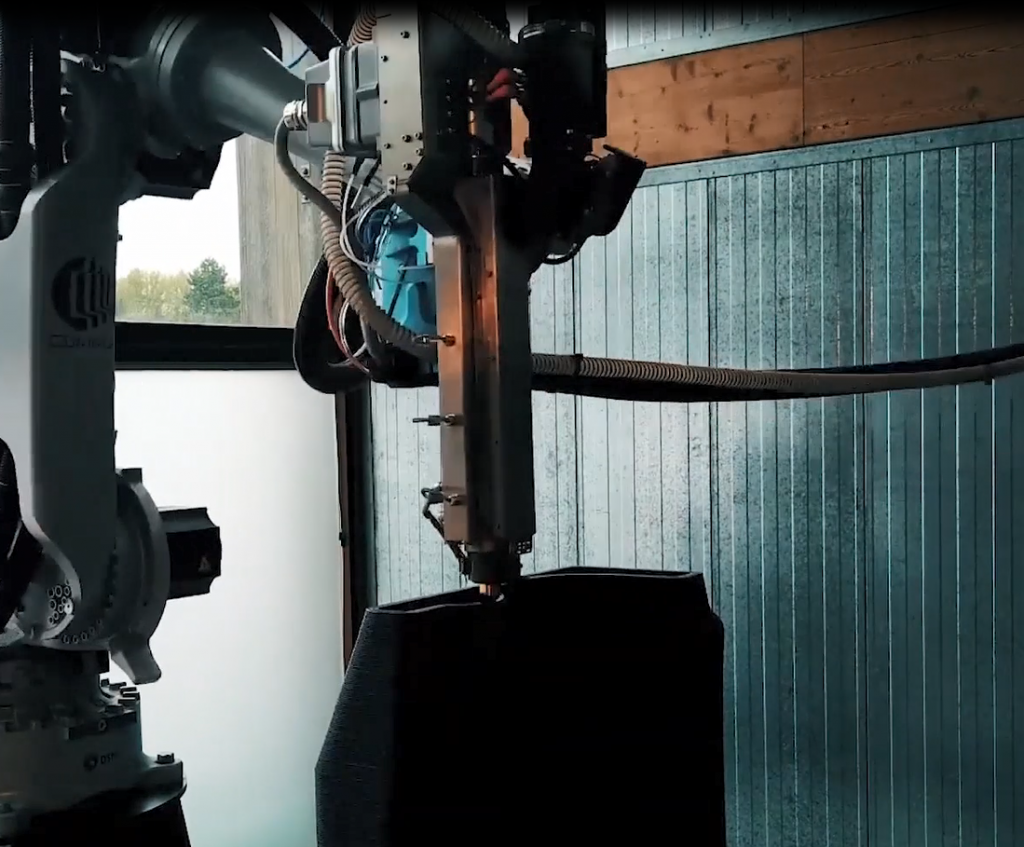

This video showcases an automated milling solution using a Comau articulated robot controlled directly via Siemens Sinumerik RunMyRobot / Direct Control.

Case Study: Automated Milling with CNC Control

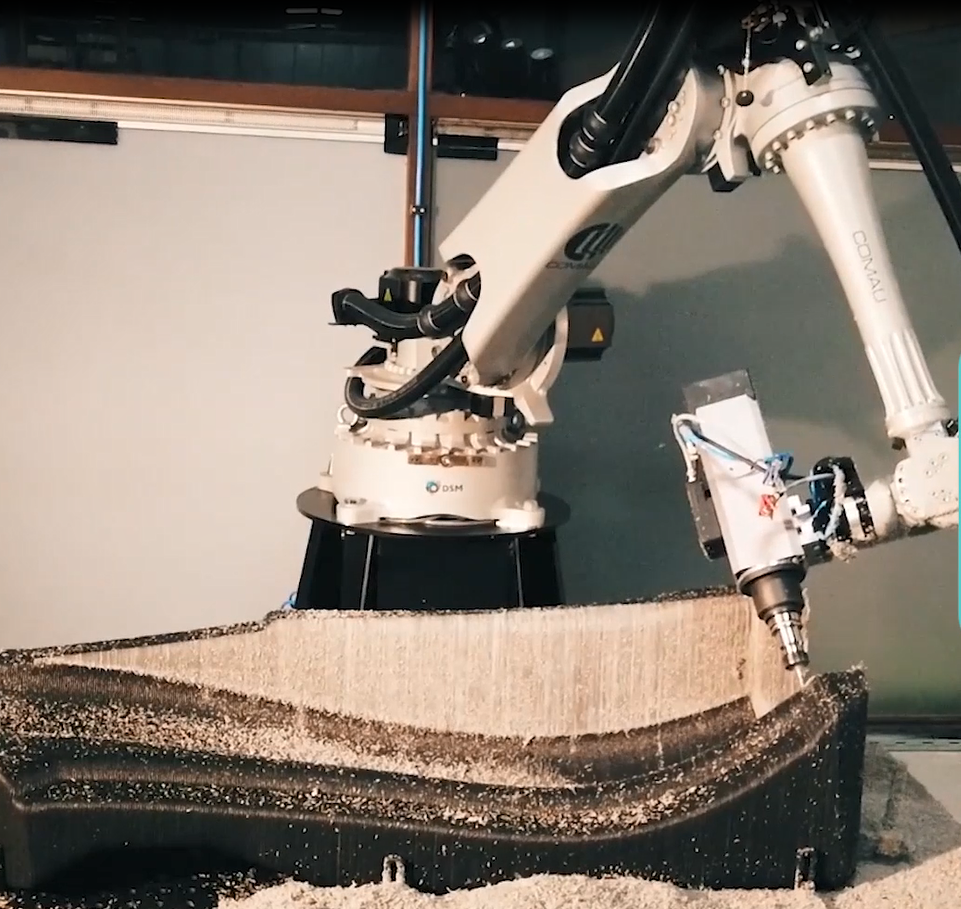

In this industrial application, a Comau robot was deployed to automate the milling of 3D printed parts, offering superior path control and high repeatability.

- The robot is fully integrated with Siemens Sinumerik, streamlining both programming and system control

- The solution ensures flawless surface finishing on complex freeform geometries

- Thanks to the elimination of a separate robot controller, the system offers reduced complexity and maintenance costs

- Operators can manage both robot and machining processes via a single CNC interface, improving usability and reducing the learning curve

This use case demonstrates how Comau’s advanced robotics can enhance precision machining workflows, particularly in hybrid manufacturing environments where additive and subtractive processes intersect

Equipped with a single milling spindle, the robot performs high-precision operations on complex 3D surfaces—eliminating the need for a standalone robot controller and ensuring:

- Seamless coordination with other machining tools

- Smooth, CNC-level path accuracy

- Compact system footprint

How the Comau Robotic Milling Solution Works

Why Choose Comau for

CNC-Based Robotic Applications?

Global leader in industrial automation

With over 50 years of experience, Comau brings industry-leading robotic technology to cutting-edge CNC applications—helping manufacturers reduce complexity while increasing process control.

Flexible, High-Precision Robotic Platforms

Comau’s robots are engineered for multi-axis precision, enabling them to handle detailed toolpaths, curved surfaces, and complex part geometries with reliability and speed.

Seamless Siemens Sinumerik Integration

Through RunMyRobot / Direct Control, Comau’s robots integrate natively into the CNC environment, enabling synchronized control of the robot and milling spindle from one interface.

Modular, Scalable Automation

Whether you’re running one cell or scaling up to a full line, Comau’s robotic technology adapts to your production needs—ensuring long-term flexibility and ROI.

About the System Integrator

CEAD is your partner for implementing 3D printing and part milling in production process. CEAD enters into long-term partnerships with its customers and assists them by building a business case and assessing the technical feasibility of the project. CEAD also investigates important aspects such as design, the required materials needed for the applications and the print strategy.

Tests and prints are included in these Proof of Concept projects. The appropriate hardware solution, derived from the results of the project, ensures the opportunity to leverage the technology to its full potential

For more information, please visit: https://ceadgroup.com/