High-Accuracy Soldering with Integrated Vision for Quality Control

In high-volume electronics production, precision and reliability are non-negotiable. Comau delivers a robotic soldering solution that combines compact design, high-speed movement, and sub-millimeter precision—ideal for delicate components and modular cells.

Combining Comau’s robotic expertise with ETNEO’s advanced soldering technology, this solution delivers consistent, high-quality soldering results for electronics manufacturers.

Smart Soldering Automation in Electronics Assembly

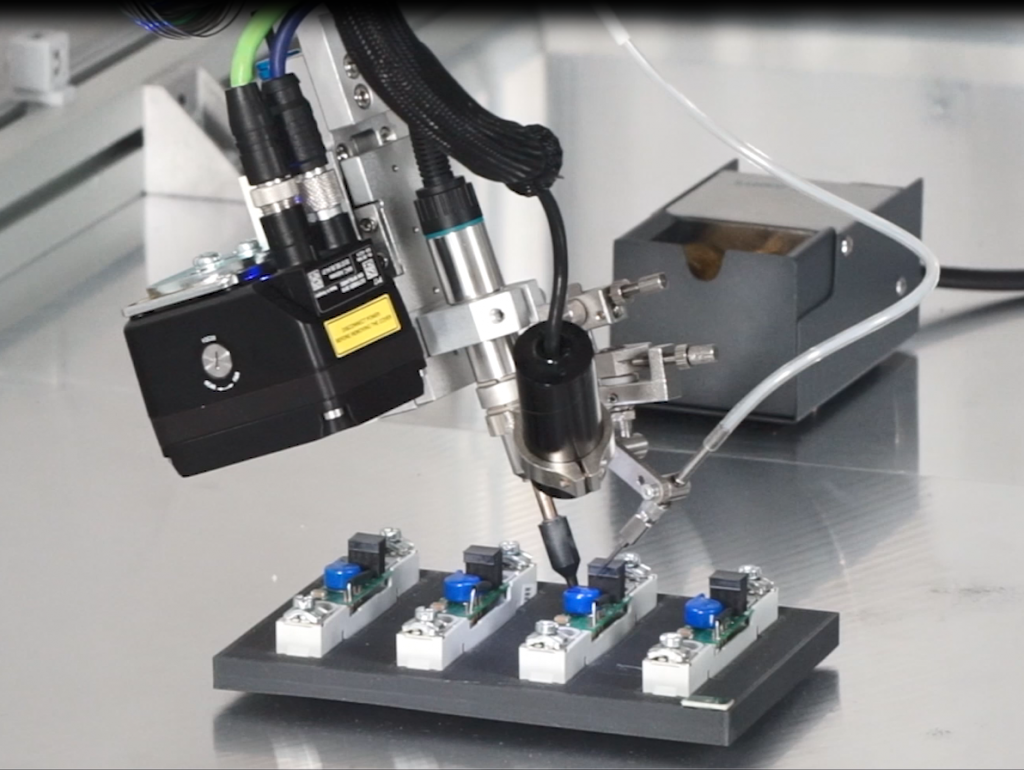

This video highlights an automated soldering cell featuring a Comau Racer-3-0.63 robot equipped with a dispensing-soldering system and an integrated vision-based quality control unit.

Case Study: Precision Robotic Soldering for Electronics

At a high-volume electronics manufacturing facility, Comau deployed a fully automated soldering cell designed to handle intricate components with precision and consistency.

- The Comau Racer-3-0.63 replicates the accuracy of manual soldering—even in space-constrained cells

- A built-in vision system checks each solder point in real time, ensuring 100% quality control

- The robotic cell integrates directly into the existing production line with minimal downtime

- An intuitive programming interface simplifies operation and accelerates changeovers

- The system delivers reliable, flexible performance with full support for evolving product designs

Comau’s robotic expertise enables electronics manufacturers to automate soldering with confidence, precision, and future-proof scalability.

The solution ensures:

- Consistent defect detection and process traceability

- Accurate soldering in tight spaces

- Easy programming and quick deployment

- Seamless integration with conveyor systems

How the Comau Robotic Soldering Solution Works

Why Choose Comau for

Electronics Soldering?

A Global Leader in Automation for Over 50 Years

Comau provides trusted, high-precision robotics for industries where speed, space optimization, and accuracy are essential—especially in electronics manufacturing.

Robotics Designed for Precision and Compact Environments

The Racer-3-0.63 robot delivers fast, repeatable motion with a small footprint, enabling seamless operation in densely packed production cells.

Integrated Quality Control & Vision Technology

By combining robotic soldering with built-in vision control, Comau ensures process reliability and zero-defect quality assurance, aligned with the highest electronics manufacturing standards.

Scalable, Customizable Automation

Whether you’re producing a single PCB type or managing multi-product lines, Comau’s modular approach ensures your automation evolves with your production needs.

About the System Integrator

ETNEO specializes in advanced soldering solutions for electronics manufacturing, offering a full portfolio of products including integrated vision systems, proprietary soldering software, automatic alloy feeders, tip cleaning systems, nitrogen systems, and custom soldering tips.

With extensive experience in electronics assembly, ETNEO combines high-performance equipment with real-time support to help customers achieve consistent soldering quality and optimized process efficiency.