Nanjing, Sep 29, 2025

The 2025 Yangtze River Delta Digital Transformation Conference was held in Nanjing on September 25–26 under the theme of advancing new productivity in manufacturing. Organized by the Yangtze River Delta Digital Co-Development Alliance, the event gathered experts from enterprises, associations, research institutes, and universities to explore how digitalization is enabling high-quality development across the manufacturing sector.

At the main forum, Zhenshu Li, Comau Head of Controls Engineering PWTA APAC, delivered a keynote titled “Empowering Smart Manufacturing through Digitalization.” He outlined how digital technologies are being applied to optimize production processes, enhance operational efficiency, and support the development of smart manufacturing systems. Drawing on Comau’s experience in areas such as smart factories, data-driven production management, and AI applications, his presentation illustrated the practical value of digitalization in manufacturing.

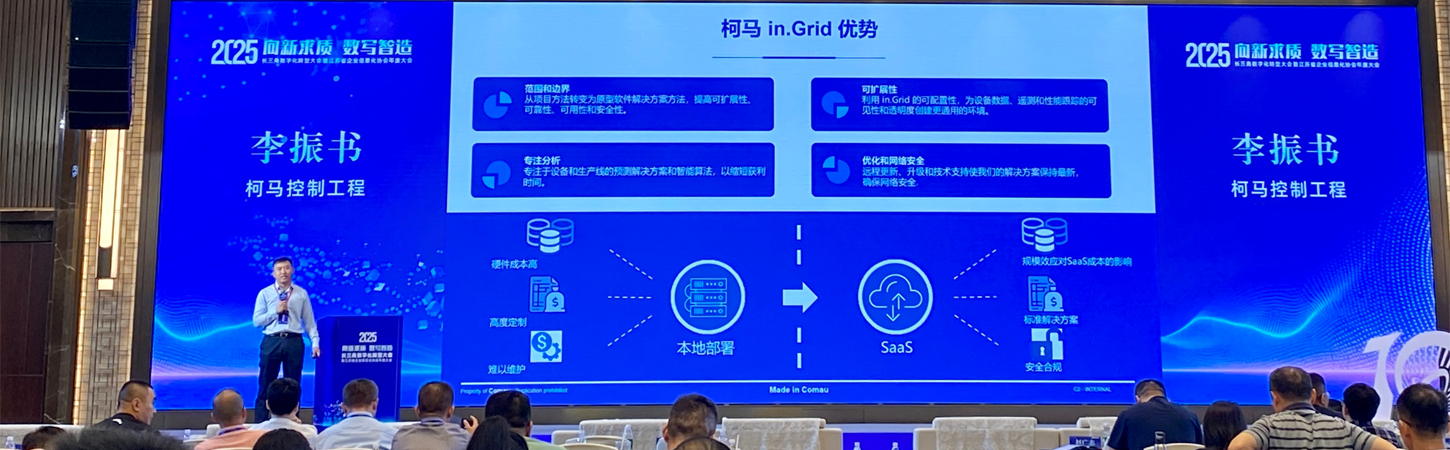

Mr. Li presented examples of Comau’s proprietary solutions, including the in.Grid digital platform and the MI.RA (Machine Inspection Recognition Archetypes) family of vision systems. The in.Grid platform integrates automation equipment, production processes, and analytics to provide real-time monitoring, efficiency optimization, and transparent, paperless management. It is available both as a cloud service and as stand-alone software, enabling rapid deployment in single or multiple factories. The MI.RA portfolio, equipped with embedded AI features, delivers flexible and accurate vision capabilities that support applications such as intelligent inspection, adaptive guidance, and collaborative robotics.

With Industry 4.0 advancing worldwide, the demand for digital transformation continues to grow, particularly in areas such as industrial simulation, digital twins, and product lifecycle management. Comau is responding with increased investment in R&D, a stronger focus on digital and software innovation, and the development of a global partner ecosystem. Through these efforts, Comau is helping manufacturers unlock insights from operational data, make more-informed decisions, and achieve higher productivity while reducing energy consumption and maintenance costs—supporting the transition toward more efficient, intelligent, and sustainable manufacturing.