Porto, September 12, 2025

Comau presented its vision on the strategic use of Artificial Intelligence (AI) in the manufacturing sector at ETFA 2025, the 30th edition of the IEEE International Conference on Emerging Technologies and Factory Automation, held from September 9 to 12 in Porto, Portugal. This internationally renowned event brought together experts, companies, and industrial operators to share innovative solutions and challenging projects in the field of factory automation, with a strong focus on enabling technologies.

As part of a packed program of events, Giovanni Di Stefano, Head of Advanced Robotics at Comau, spoke at the event on September 12, giving a presentation on “Industrial Heritage For Training Advanced Robotics Neural Networks,” in which he outlined Comau’s commitment to developing intelligent applications based on machine learning to optimize the efficiency of robotic plants and automation systems.

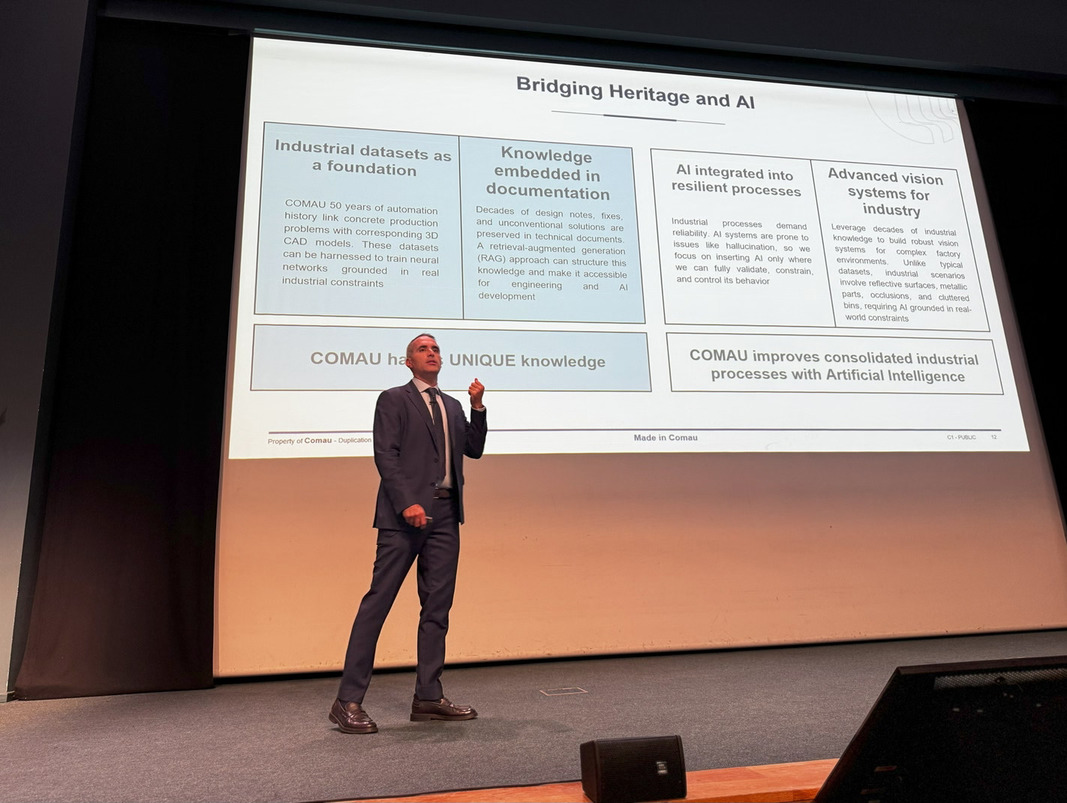

As Di Stefano explained, in an industrial landscape characterized by the large-scale use of Artificial Neural Networks aimed at multiplying human skills and optimizing processes, Comau’s strength lies in its ability to leverage unique skills and knowledge to develop customized AI models tailored to the specific technical needs of its customers, both old and new, across all sectors, not just the automotive industry. This is possible thanks to Comau’s more than 50 years of experience in industrial automation, an experience that has already been largely digitized thanks to many years of experience in PLM (Product Lifecycle Management) systems, and the resulting availability of a large archive of industrial data that has enabled it to train neural networks on real use cases to manage complex industrial applications.

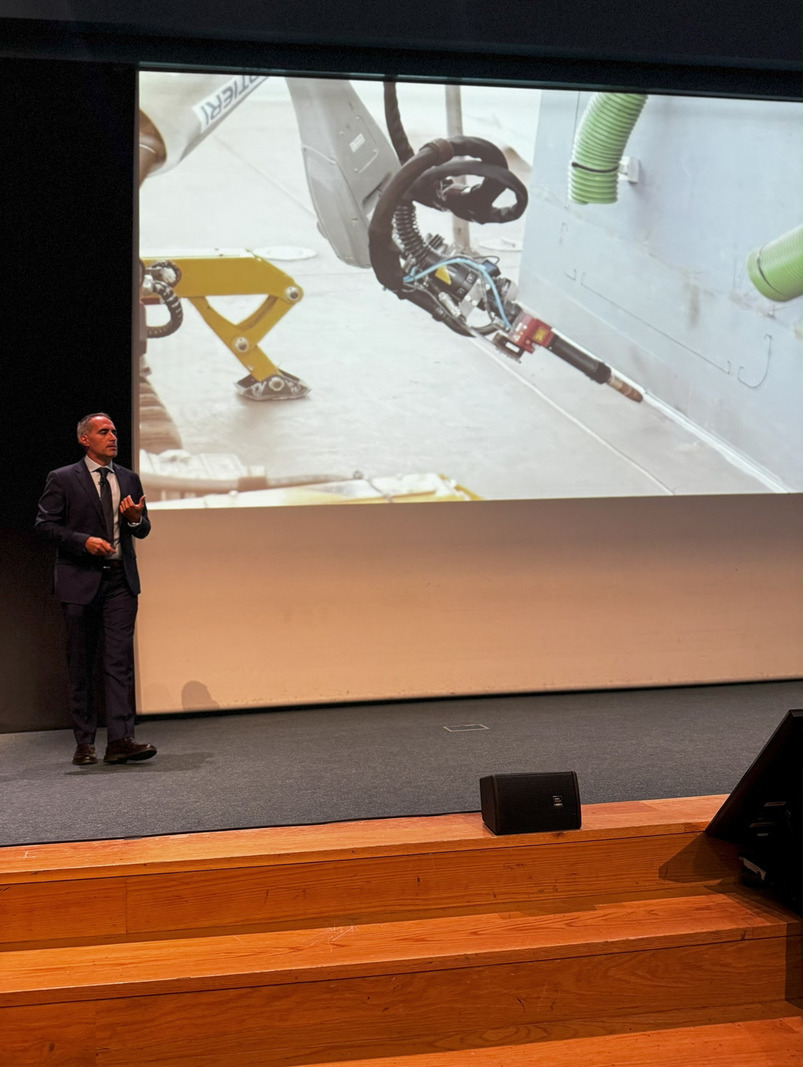

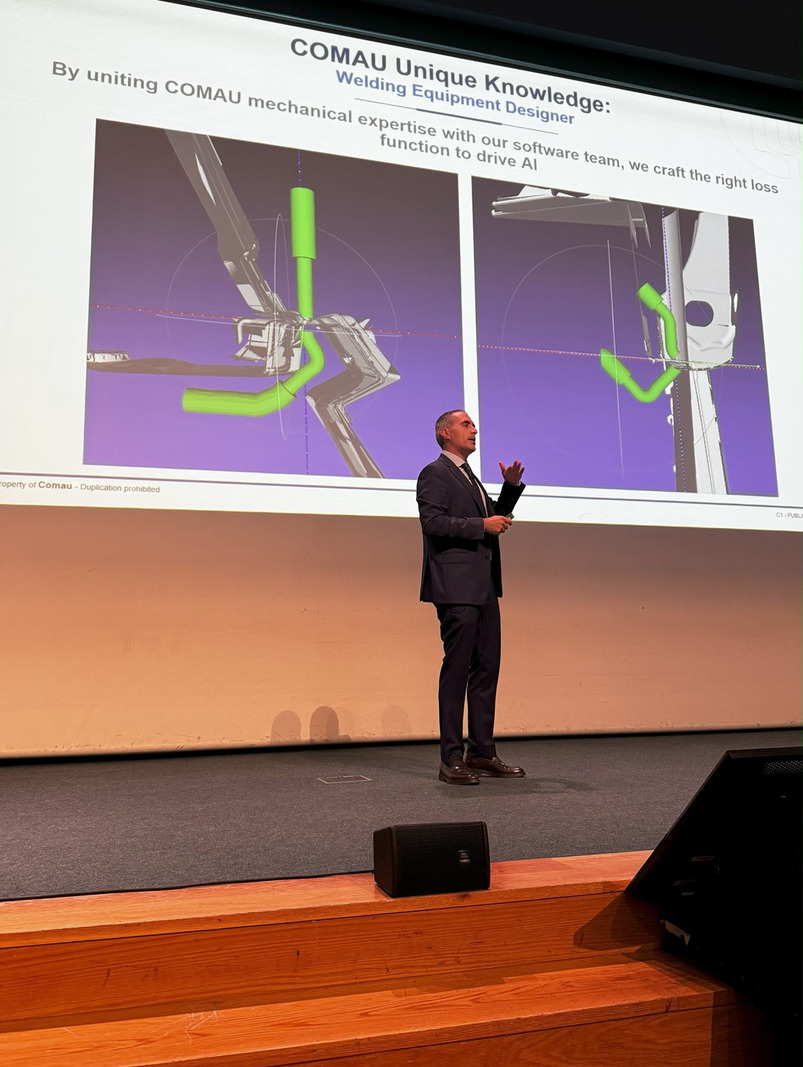

Comau is currently experimenting with the use of AI to enhance innovative technologies and applications in various sectors. In particular, the company has developed proprietary intelligent tools to calculate the actual stiffness of robot joints in order to ensure better movement quality. AI algorithms have also been used to automatically design robotic welding gripper arms more quickly and accurately, reducing design costs and time. Another successful example is the MI.RA (Machine Inspection Recognition Archetypes) family of intelligent vision systems, specifically MI. RA/OnePicker, an AI-based solution that allows robots to autonomously pick up generic and heterogeneous objects in the environment, increasing productivity and efficiency. Added to this is MI.RA/Thermography, an innovative in-line quality verification and control system that uses AI to verify the quality of welding processes in the assembly of new-generation batteries.

“It was an honor to participate as a speaker at ETFA 2025, an event of great importance in the global debate on technological innovation and the use of intelligent solutions for industry. Thanks to customized AI tools, automation companies such as Comau can gain significant competitive advantages in the market, improving productivity and processes without having to resort to developing new and expensive algorithms. We believe that the use of AI is not a risk for the future of the industrial system but a decisive business opportunity. It allows us to leverage a wealth of data, acquired over many years of activity, to train proprietary AI models through specific and consolidated skills, which are essential for making our technologies increasingly advanced and improving customer productivity in a variety of applications”.

Giovanni Di Stefano

Head of Engineering Advanced Robotics at Comau

Find out more about ETFA 2025 and Comau’s presentation on the event website https://etfa2025.ieee-ies.org/program/index.html