Enhancing Repeatability and Processing Accuracy

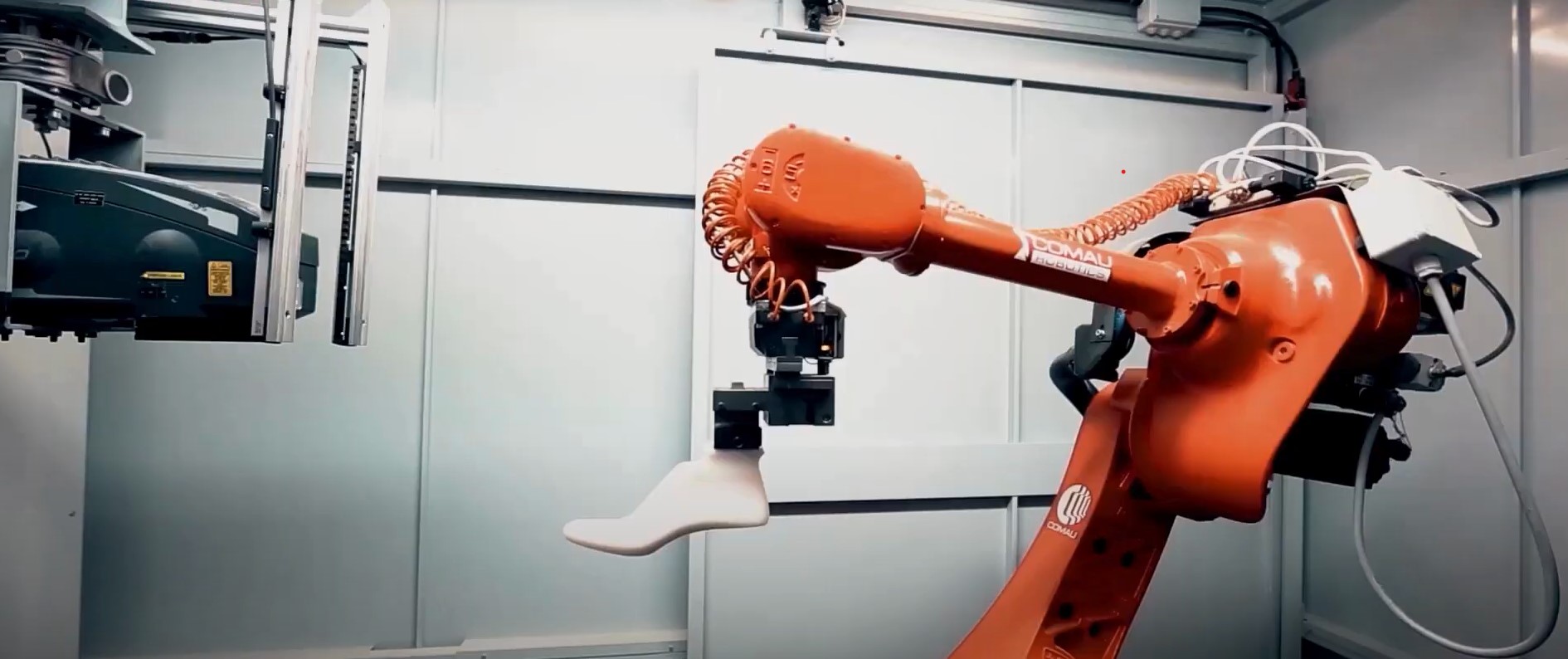

In collaboration with Formificio Enzo, Comau implemented a laser marking solution using the Comau NS-12 articulated robot, designed to ensure high processing quality, positioning repeatability, and precise orientation of reference points during the marking of HDPE lasts for the footwear industry.

This system is part of the innovative LPS – Last Printing System, which helps shoemakers by delivering perfectly identical reference coordinates across all processed models.

Smart Automation for Footwear Mold Marking

This video showcases the robotic cell designed with Comau NS-12 to automate the precise laser marking of footwear molds.

The robot picks up lasts from designated slots, positions them under the laser in multiple angles, and ensures consistent orientation and marking precision for each product.

Case Study: Laser Marking with NS-12 in the LPS System

To meet Formificio Enzo’s need for precision and consistency in marking plastic lasts, Comau delivered a fully automated solution with:

- Accurate 3D positioning of each last using NS-12’s articulated reach

- Permanent laser marking of technical, demographic, and geometric data

- Repeatability in orientation, ensuring identical coordinate systems on each model

- Safe, enclosed operation area with laser shielding and automatic signaling

The robotic solution enables full traceability and improved process control in the production of footwear prototypes and mass-produced lasts.

“Our production can be divided into two distinct departments, the first of which is dedicated to the creation of wooden models and prototypes, whereas the second deals with the mass productions of HDPE lasts,” explains. “In the modelling department, the development of prototypes can benefit from the expertise and experience of our master designers who, in turn, make use of the most advanced information technologies (CAD, CAM, ICT and structured light optical scanning systems) in order to turn a stylist’s ideas – even simple sketches – into unique models.”

How the Comau NS-12 Laser Marking System Works

Why Choose Comau for Laser Marking Automation?

Global Expertise in Advanced Robotics

With more than 45 years of automation leadership, Comau brings advanced robotic solutions to industries where precision and consistency are critical—like footwear, medical, and consumer goods.

High-Performance Robots for Accuracy and Flexibility

The NS-12 is ideal for applications requiring multi-angle, multi-pass handling of small to medium objects, delivering excellent performance in both prototype and high-volume environments.

Seamless Integration with Laser Systems

The robot is fully integrated with the LPS cell, managing positioning, safety controls, and laser activation in a unified workflow, enhancing process speed and removing the risk of manual error.

Customized for Specialized Needs

The LPS system supports custom layouts and workflows, adapting to various types of lasts and marking requirements with flexibility, reliability, and guaranteed repeatability.

About the System Integrator: FORMIFICIO ENZO

Fornificio Enzo’s attention to the quality of the product comes from the care they take of it.

Fornificio Enzo constantly stare at new technologies, conscious that hand-made tradition represents a cultural and technique store they can’t leave out of consideration. They are convinced that joining this two elements is the best way to develop an excellent and reliable product.

They track the production process and operating procedures to get a continuous improvement able to guarantee the best quality standards on product. The trust of customers is for them the best quality certificate.