Flexible Robotic Palletizing for the Food Industry

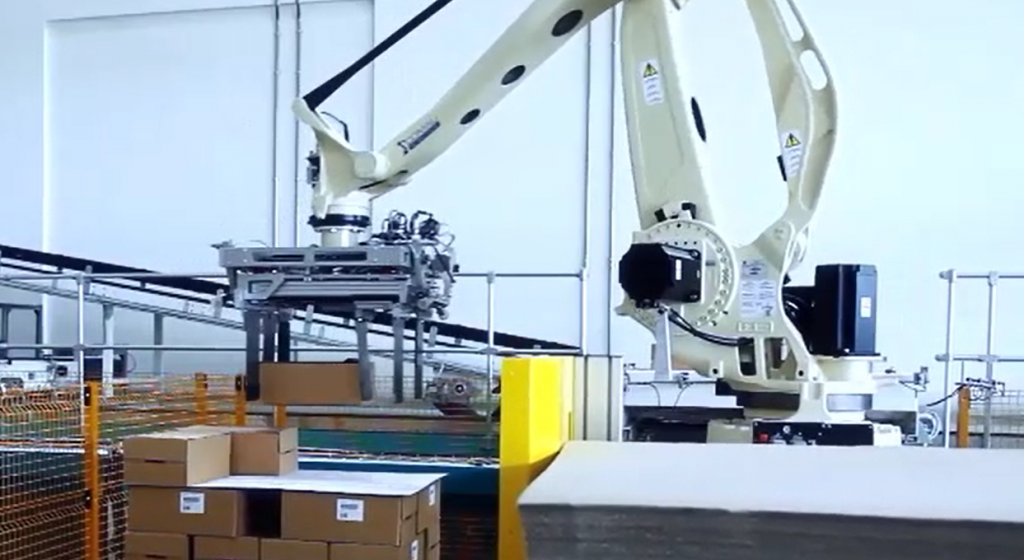

Comau robots are at the core of a high-performance robotic palletizing solution designed to ensure speed, flexibility, and product integrity for an highly automated pasta packaging.

Developed in collaboration with a specialized system integrator, the application enables:

The result is a fully automated, high-performance solution designed to meet the evolving needs of the food industry.

Flexible Robotic Palletizing in Action

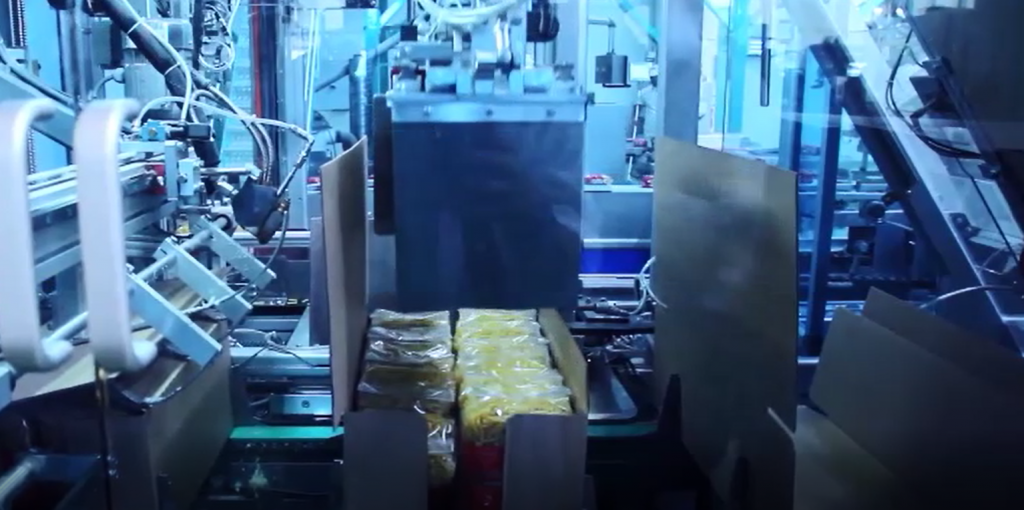

This video showcases a fully automated palletizing solution driven by Comau’s robotic technology, developed to support Ghigi’s high-speed pasta packaging line.

The system features four Comau palletizing robots, capable of managing diverse product types with varying box sizes, shapes, and weights. Integrated with the existing packaging process, it ensures seamless product flow, batch flexibility, and maximum reliability—even in the face of non-standard packaging or reduced materials.

Case Study: End-of-Line Robotics for Pasta Production

At the San Clemente production site, spanning over 100,000 m², Comau’s robotic solution plays a key role in managing the packaging flow of pasta products destined for multiple international markets.

- 4 Comau palletizing robots handle boxes with varying sizes and weights

- The system automatically adjusts stacking patterns and pallet types

- Full integration with upstream packaging lines ensures real-time product flow

- Robots compensate for weight and shape variations typical in pasta production

- Designed to operate with minimal downtime and easy reconfiguration

This automation system reflects Comau’s commitment to supporting Italian manufacturing excellence with smart, scalable robotics.

How the Comau Robotic Palletizing Solution Works

Why Choose Comau for End-of-Line Automation?

A Global Leader in Industrial Automation

With over 50 years of experience, Comau is trusted by top manufacturers to automate complex production and packaging processes—especially in the food & beverage industry.

Precision Robotics Built for Flexibility

Comau palletizing robots offer high-speed performance, multi-format adaptability, and compact design, making them ideal for handling diverse product lines in space-constrained environments.

Ready for Integration, Built to Scale

Comau’s systems are designed for seamless integration into your existing lines, with minimal disruption. From layout to logic, every aspect supports high-volume, high-variability production.

Custom Automation for Real-World Needs

No two food producers are the same. Comau customizes each solution based on your packaging formats, production layout, and business goals—ensuring the system scales with your growth.

About the System Integrator: TIBER PACK

Founded in 1968, Tiber Pack began as a mechanical workshop serving the Buitoni pasta factory. Over the decades, it has evolved into a leading provider of automated packaging systems for the food, fruit & vegetable, general industry, and tissue sectors.

Driven by innovation and a passion for excellence, Tiber Pack combines customized solutions with cutting-edge technology, making it a trusted automation partner for leading companies in Italy and beyond.