Automated Palletizing Station for Food & Beverage Industry for KIMBO

To meet growing demands for flexibility, efficiency, and space optimization, Comau developed a compact robotic palletizing station for a major coffee producer in Southern Italy. Designed to fit within tight spatial constraints and handle multiple product formats, the solution ensures:

With Comau’s advanced robotic technology at its core, the solution delivers a future-ready system tailored to the evolving needs of the food & beverage sector

Robotic Palletizing in Action: Optimizing Coffee Production

This video presents an automated palletizing station powered by Comau robotics, specifically designed to operate in space-limited environments while maintaining high performance and traceability.

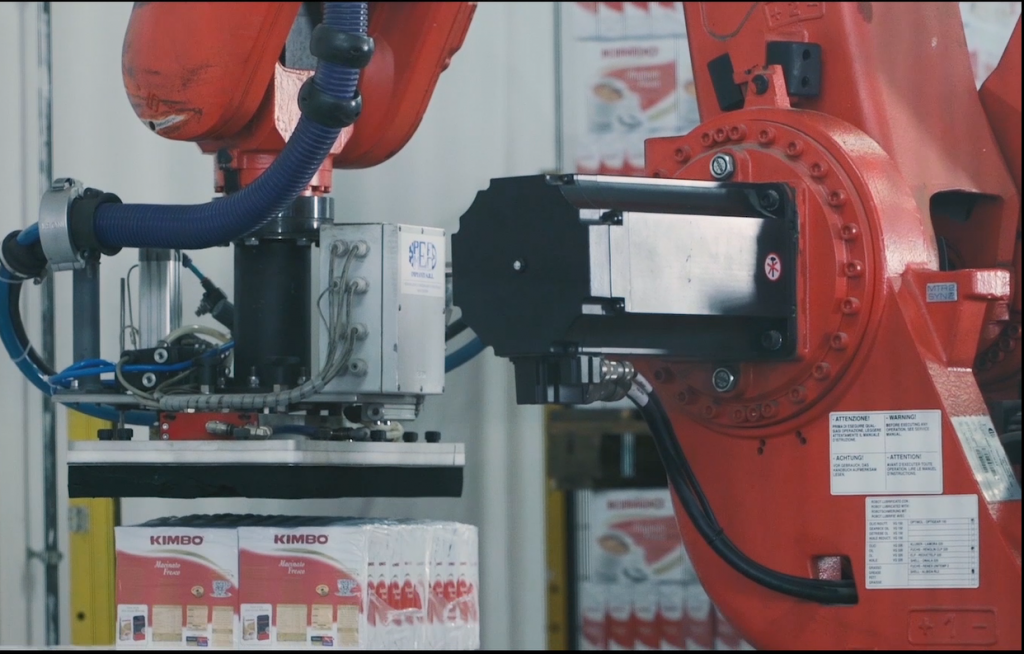

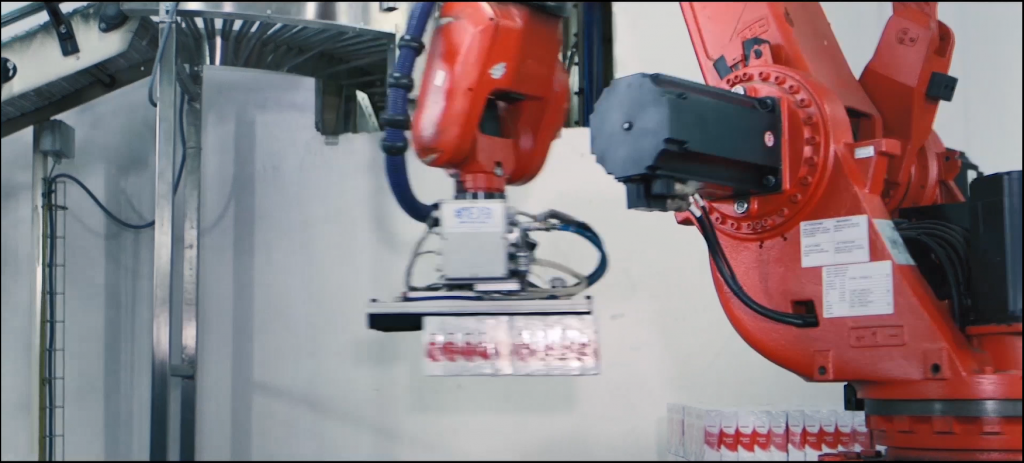

Equipped with a pneumatic gripper, the robot manages both product packs and pallets, offering complete flexibility and operational continuity. The result is efficient palletizing, reduced manual handling, and streamlined product flow for the coffee packaging process.

Case Study: Flexible Robotic Palletizing for Coffee Packaging

At a coffee production facility, an existing palletizing system was no longer meeting the demands of flexibility, reliability, and spatial efficiency. Comau implemented a new robotic palletizing cell designed to:

- Operate within height and space constraints

- Manage multiple product formats and stacking patterns

- Ensure traceability through batch indexing

- Maintain uptime with low-maintenance components

- Enable reprogramming via a user-friendly interface

This application highlights Comau’s ability to adapt industrial robotics to real-world production needs, delivering an end-of-line automation system that is reliable, scalable, and easy to manage.

“The need to use this robotic station,” explained Johnny Frank Baldoni, manager of the Kimbo plant in Melito di Napoli (Naples), “was dictated by an existing solution whose efficiency no longer complied with our business needs. So we had to redesign this operational phase, while complying with limitations in terms of space and height. At the same time, the system had to guarantee high flexibility, operational continuity and a low-maintenance impact in the broadest sense, while being easily programmable with an extremely user-friendly interface.”

How the Comau Robotic Palletizing Solution Works

Why Choose Comau for End-of-Line Automation?

Global leader in industrial automation with decades of innovation

With over 50 years of experience, Comau designs intelligent automation systems that meet the real-world challenges of modern production—from layout constraints to evolving packaging needs.

Precision robotics designed for performance and flexibility

The Comau robot installed in this application is engineered for high-speed, accurate palletizing, with the adaptability to handle diverse formats and stacking patterns, all within compact footprints.

Seamless integration with existing systems

Comau ensures flawless integration of its robotic cells into your current production infrastructure. This includes traceability, material flow management, and future product line updates—without disrupting operations.

Custom automation, built around your production

Every detail of the robotic palletizing solution is customized to your needs—from conveyor layout and batch tracking to reprogramming tools and gripper configuration—ensuring maximum return on automation investment.

About the System Integrator: REF.MEC

REF.MEC Impianti S.r.l. Industrial automation was fouded by two partners, Giuseppe and Raffaele Pellegrino, and grew thanks to their effortless commitment in developing solutions for the mechanical and industrial automation sector. All this makes REFMEC Impianti a flexible and versatile partner for their customers, always operating with high quality standards, customized solutions, punctuality and precision. Today REFMEC Impianti operates in Italy, boasting among their customers some of the largest companies on the Italian industrial scene.