Electric vehicles (EVs) have emerged as a prominent solution for reducing carbon emissions and the reliance on fossil fuels. With advancement in battery and motor technologies, coupled with government initiatives to support this huge transformation, major automotive companies have set ambitious targets for electrification and are intensifying their e-Mobility transition efforts.

In tandem, we are seeing catalyzing technological advancements within the EV sector as companies like Comau increase their research and development efforts to enhance the efficiency, reliability, and performance of electric vehicle solutions. By focusing on the development of cutting-edge electric drive assembly technologies, Comau aims to play a crucial role in shaping the future of electric vehicles and promoting innovation and sustainability.

EV Manufacturing: Embracing a New Era

The electrification of the automotive industry is an incremental process, transitioning from conventional internal combustion engines to purely electric power. Although the electric powertrain system remains at the core of the vehicle, market demand for electrified powertrains now encompasses pure electric, plug-in hybrid, supercharged, and future-proof hydrogen power.

As an early adopter and system integrator in the new energy vehicle sector, Comau is leveraging decades of knowledge and innovative experience in powertrain technology to offer comprehensive solutions that range from individual components to entire systems, and cater to various electrification applications.

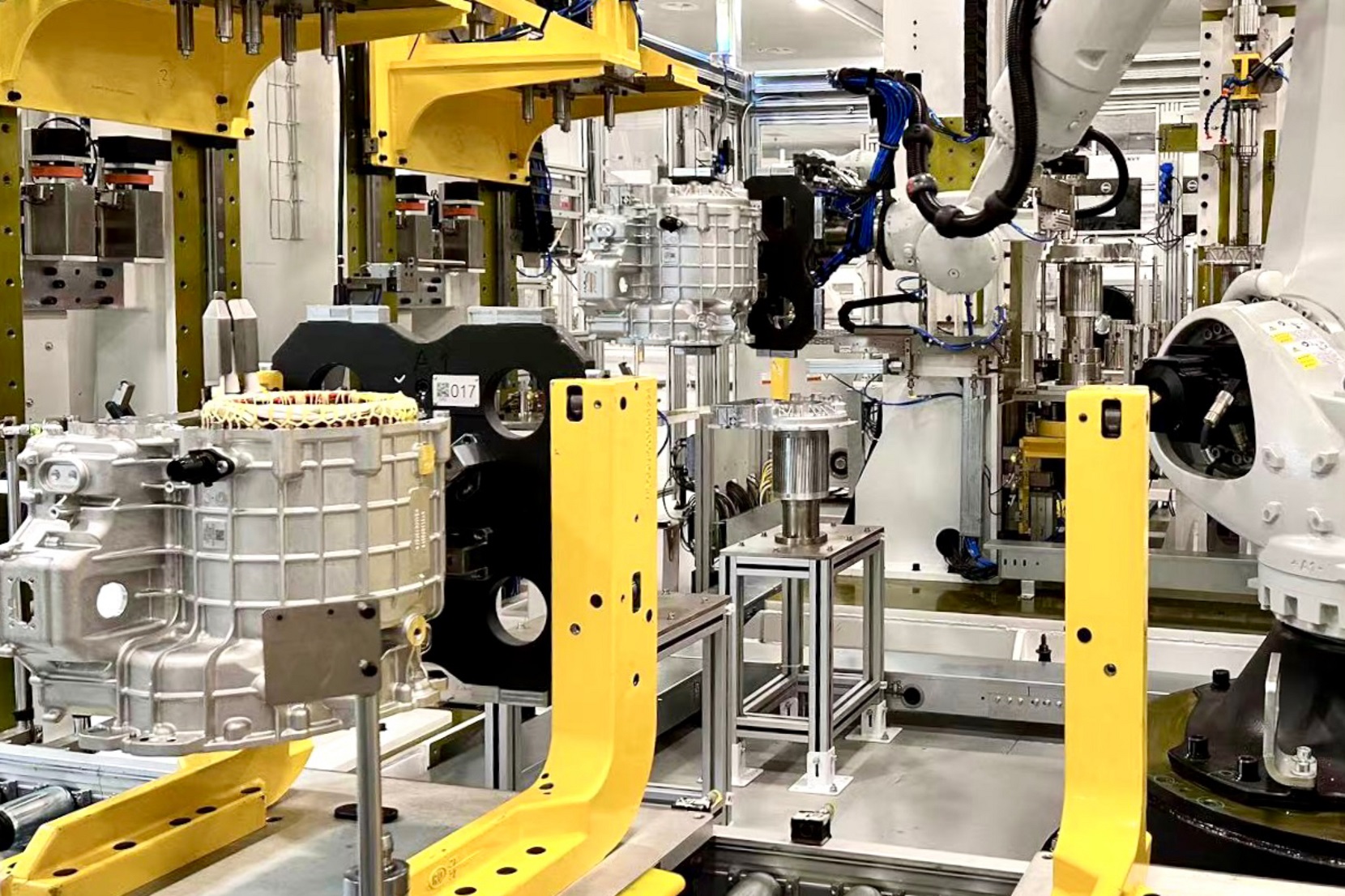

In terms of e-powertrain solutions, Comau implements customized solutions across the entire value chain instead of focusing solely on individual components. This includes electric drive assembly, stator-rotor assembly, electric controller assembly, electric transmission housing machining, and more. Furthermore, cutting-edge technological solutions are employed at each process link, from stator heat insertion, stator and rotor assembly, shaft assembly into the housing, gearbox assembly, inverter assembly, and beyond. Additionally, Comau has developed full competence to offer a turnkey solution for hairpin stator assembly lines, through independently developed hairpin stator core assembly stations scheduled to be launched in the coming months.

To cite a few real-world applications, Comau and NIO have reached a series production capacity of 1 million EDS per year thanks to a comprehensive solution that includes primary lines (electric motor assembly lines, gearbox production and inverter assembly lines) as well as EOL (end-of-line) test processes. These measures ensure fast and reliable co-line production for NIO’s third-gen induction and permanent magnet motors, both of which are integral parts of its proprietary electric drive systems (EDS). Similarly, Comau has provided Geely Vremt with a high-speed e-drive assembly solution aimed at automating the entire end-to-end production process for their electric motors, gearboxes and inverters. Notably, this deployment has effectively doubled the automation rate for this high-volume assembly line.

Versatile Electrification Solutions for Every Application

In today’s rapidly evolving market, manufacturers must remain agile to meet the demands of shifting consumer preferences. This necessitates flexibility and speed in both development and market introduction, presenting a significant opportunity for pioneers in e-mobility, such as Comau.

In addition to its vast portfolio of e-drive technologies, Comau’s solutions portfolio includes automated manufacturing systems for battery cells, modules and complete packs (with any cell format).

Comau offers a range of systems for different stages of the production process including battery cell forming technologies. With a 360° portfolio of products, processes and technologies, Comau can handle everything from prototyping and pre-production to mass manufacturing, and all the way to end-of-life battery recycling.

Modular design for enhanced Flexibility, Efficiency, and Accuracy

With the rising demand for customized products and the need for fast iterations and small batch sizes in the new energy vehicle segment, manufacturers are increasingly seeking reconfigurable production lines. OEMs anticipate the ability to adjust the production line composition based on product changes, driving the need for greater modularity, design standardization, and software flexibility.

Comau’s modular design philosophy offers automotive manufacturers the versatility to respond quickly to market demands and technological advances. By employing standardized modules that can be easily interchanged and reconfigured, manufacturers can adapt their production lines to accommodate NEV models or emerging technologies.

Extensive standardization of production processes can also lead to faster time-to-market and lower development costs for customers. Finally, Comau’s adoption of simultaneous engineering methods with customers, from product design to product and process integration design, enables manufacturers to ramp up production rates while maintaining high product quality, ultimately improving profitability and competitiveness.

Integration of Digital Technologies in E-Mobility Solutions

Artificial Intelligence (AI) and the Internet of Things (IoT) are revolutionizing the automotive industry, driving advancements in connectivity, automation, and predictive maintenance. In line with this trend, Comau is utilizing digital technologies to enhance e-mobility solutions and improve operational efficiency. Indeed, throughout the production process, Comau’s digital solutions assist customers in optimizing production scheduling and processes through real-time data collection and analysis. This enables intelligent control and automation of production lines, leading to improved production efficiency, equipment utilization, and timely issue resolution. These same digital solutions can be used as part of a preventive maintenance strategy to reduce unplanned downtime and ultimately increase production capacity.