Comau has provided LiNa with a detailed technology roadmap to automate their innovative cell manufacturing process

• The companies have developed and validated an innovative design concept to automate manufacturing of next-generation sodium-based battery cells

• This cooperation with LiNa, a leader in solid-state sodium battery technology, underscores Comau’s steadfast commitment to electrification

• Comau now covers the entire battery manufacturing value chain from cell formation through end-of-life recycling

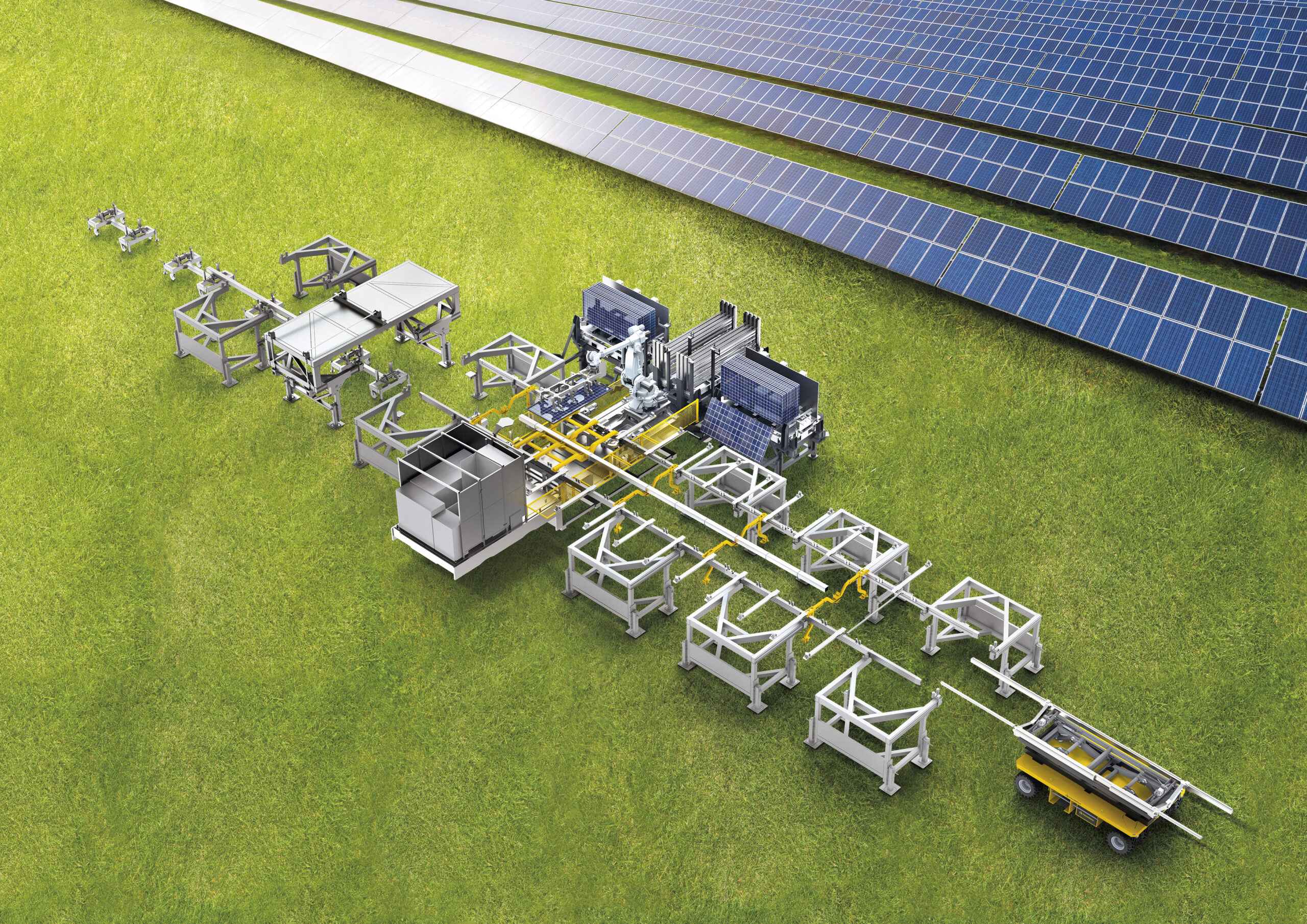

Turin, December 5, 2023 – Comau has joined forces with LiNa to design an innovative and scalable manufacturing solution for solid-state sodium-metal-chloride battery cells. Through simultaneous engineering, the team has finalized a concept design, allowing LiNa, a leader in low cost solid-state sodium battery technologies, to automate their battery production process. The companies intend to validate the sustainable, safe, and efficient oxygen-free dry box environment as a step towards larger-scale manufacturing.

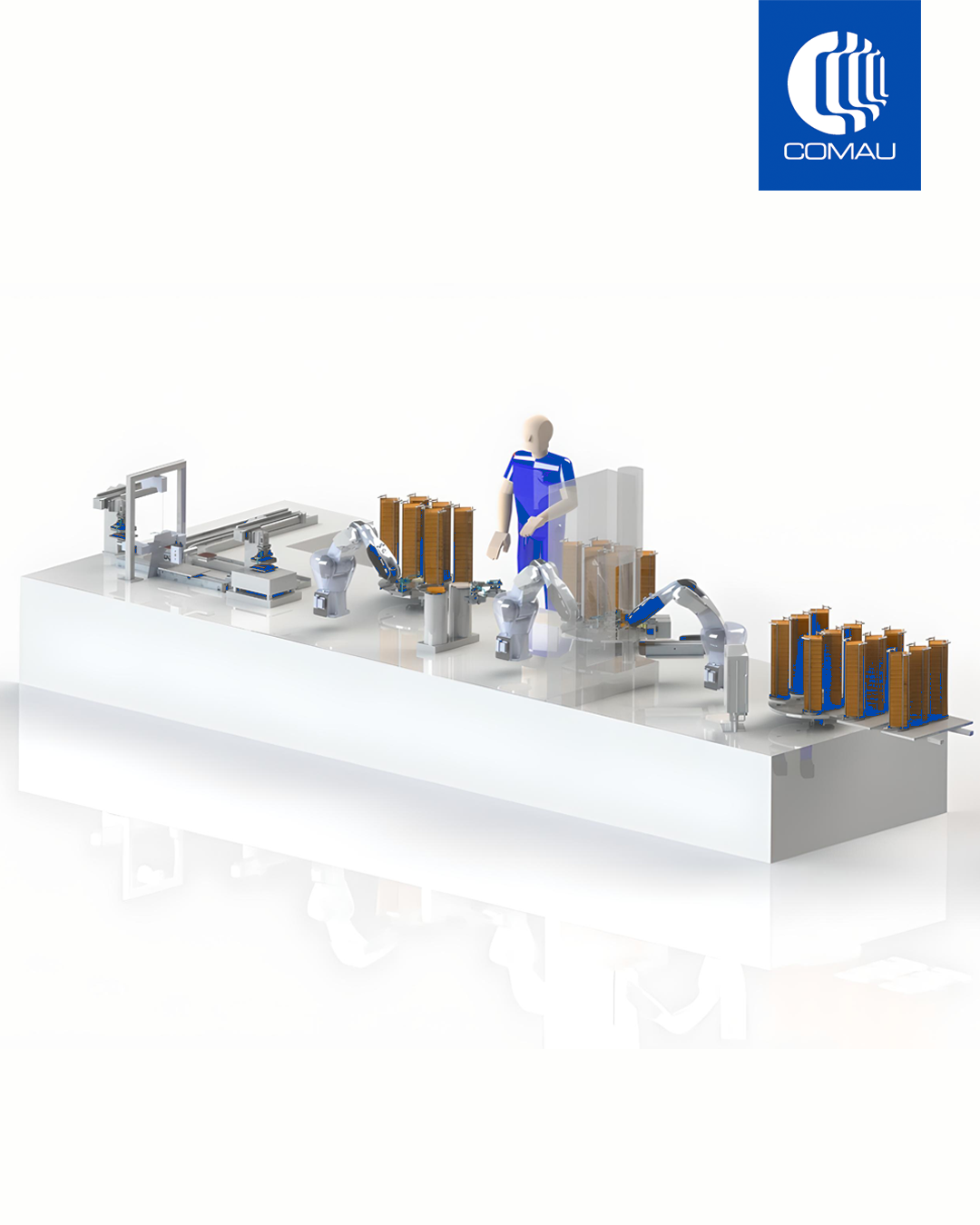

Comau and LiNa engineers worked in tandem to design the enclosure and handling equipment for the specific components of the solid-state battery cell as well as to identify and integrate existing commercially available equipment, including Comau’s cleanroom classified, high-speed Racer-5 SENSITIVE ENVIRONMENTS articulated robots into the design. This collaborative approach enabled Comau to suggest modifications to LiNa’s existing manufacturing methodology with the aim of optimizing process dynamics in the move to automatic cell assembly.

Highlighting its 50 years of expertise in automation and continued investments in the electrification sector, Comau has provided LiNa with a detailed technology roadmap to automate their innovative cell manufacturing process. Furthermore, leveraging its ongoing development of new manufacturing technologies for next-generation battery cells, Comau is increasingly able to provide a 360° cradle-to-grave e-Mobility strategy.

Development advances in sodium-based battery cells are driving the deployment of a safe, sustainable energy source that can be used at high temperatures. Instead of completely replacing lithium-ion batteries, next-generation solid-state sodium batteries will provide high performance energy storage that is both cost efficient and can be optimized for renewable energy integration in key solar growth markets such as India

“This automated manufacturing concept, designed with Comau’s engineering team, provides a clear technology roadmap to significantly increase production capacity of our patented battery cells. Having successfully researched the process dynamics and finalised an innovative design proposal, we are looking forward to taking the next steps in our mission to commercialise our sustainable, low-cost solid-state sodium batteries. This approach not only ensures progress and cost control but also guarantees the quality, performance and reliability of the final product.”

Kris Barr, LiNA Director of Operations

“Our steadfast commitment to energy transformation is a perfect match for a company like LiNa, whose vision and engineering competence are promoting and enabling the development of high-performance sodium-based energy storage solutions. It was a great opportunity for us to have worked side-by-side to validate a manufacturing process design that will put LiNa on the path toward larger-scale industrialization of their solid-state sodium cell technology.”

Gian Carlo Tronzano, Comau Head of e-Mobility Global Competence Center

Downloads

About Comau

Comau, a Stellantis company, is a worldwide leader in delivering sustainable advanced automation solutions. With 50 years of experience and a global presence, Comau is helping companies of all sizes in almost any industry leverage the benefits of automation.

Backed by a continuous commitment to designing and developing innovative and easy to use technologies, its portfolio includes products and systems for vehicle manufacturing, with a strong presence in e-Mobility, as well as advanced robotics and digital solutions to address rapidly growing markets in industrial sectors.

The company’s offering also extends to project management and consultancy. Through the training activities organized by its Academy, Comau is committed to advancing the technical and managerial knowledge necessary to face the challenges related to automation and leverage the opportunities of a constantly changing marketplace.

Headquartered in Turin, Italy, Comau has an international network of 5 innovation centers, 5 digital hubs, and 12 manufacturing plants that span 13 countries and employ 3,700 people. Together with its wide network of distributors and partners, the company is able to respond quickly to the needs of its customers, no matter where they are located throughout the world.

Contact Comau

You can get in touch with our Press Office and Media area,

by entering your contact information.