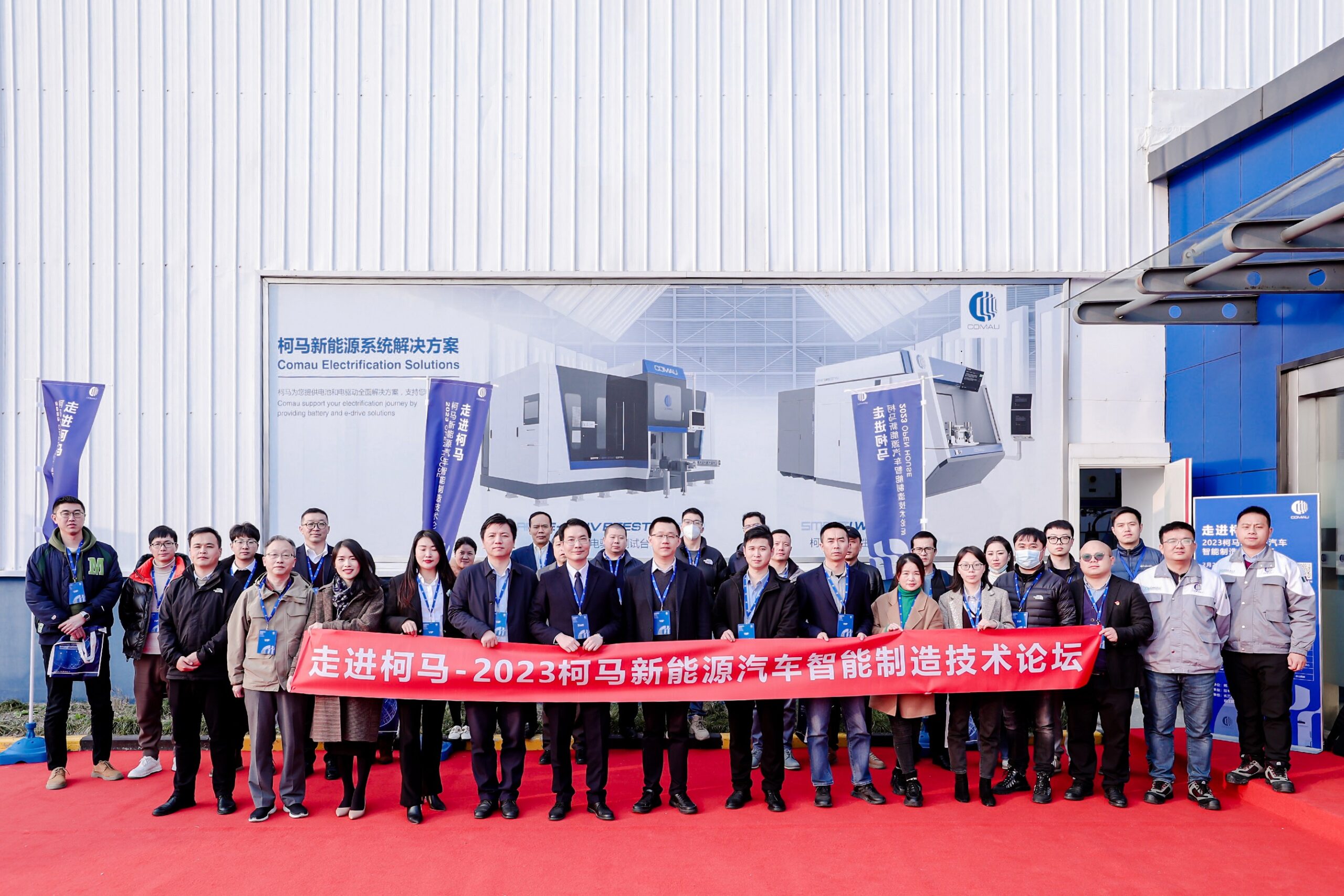

Shanghai, Feb 27, 2023 – Comau recently celebrated its Open House on e-mobility, with an additional focus on smart manufacturing and digital initiatives. The event was supported by the G60 Science and Technology Innovation Valley of Yangtze River Delta Joint Conference Office. During the event, more than 50 representatives from government agencies and customer companies gathered at Comau’s APAC Innovation Centre, in Shanghai, to share their experiences on trends in new energy vehicles (NEVs) and technology applications, and presented different application cases in the e-mobility field.

Comau has advanced experience in industrial automation, and also benefits from the group’s unique comprehensive knowledge base and long-standing technology expertise in the automotive sector. These advantageous conditions enable the company to continue to achieve breakthroughs and innovations in the rapidly growing new energy vehicles market, and to remain at the forefront of the industry with over 60 projects in electrification around the world.

The event began with an analysis of national and regional policies for the new energy vehicle industry by Dai Zhiming, head of the Industry Group of the G60 Science and Technology Innovation Valley of Yangtze River Delta Joint Conference Office. He pointed out that the new energy vehicle industry is an important part of the region’s development and is well distributed across the nine cities of the Yangtze River Delta, creating regional synergistic development. The G60 Science and Technology Innovation Valley of Yangtze River Delta will continue to focus on building new energy vehicle industry clusters and deepen the layout for energy batteries, key components and automotive manufacturing.

Gaetano Cantalupo, Comau Head of Countries Cluster APAC, highlighted the development footprint of Comau’s electrification path. With the implementation of peak carbon and carbon neutrality targets, the transformation of the global automotive industry is accelerating. At the same time, the new energy industry chain is gradually reaching its peak. Comau provides innovative technologies and solutions across the entire electric vehicle value chain, including hydrogen-based technologies, and is committed to working with customers and the industry to support a more sustainable mobility ecosystem in China and globally.

Specifically, Comau is able to cover all phases of the battery production cycle for prismatic, cylindrical and pouch formations. The company is also engaged in the design and construction of assembly systems for battery packs and in the supply of systems for the construction of cells, working in close collaboration with some of the world’s leading manufacturers. Comau is trying to anticipate the technological trends that will guide the future of electrification – thanks to a strong propensity for innovation and experimentation with cutting-edge solutions. In this regard, the company is collaborating directly with battery manufacturers, technology developers and centers of international research for the industrialization of new generation cell production processes, such as solid-state batteries.

Suo Lei, Head of Comau Technology China, explained the latest solutions use cases from the perspective of market trends and customer needs. Comau provides solutions from EV body to powertrain assembly, from rotor to motor and electric drive, from battery cells to modules and packs.

To better adapt to market changes and the challenge of digital transformation, and to achieve intelligent production, Comau integrates digital products and solutions to transmit, process and analyze connected data and information to make production processes faster, smarter, more flexible and dynamic. In doing so, Comau’s solutions help improve production efficiency and product quality, while reducing operating and production costs.

Li Zhenshu, Comau China Control Engineering & Digitization Dept. Manager, presented the Comau in.Grid platform, which helps manage and monitor production processes and machine performance by connecting Comau and non-Comau devices to meet manufacturing companies’ needs for end-to-end management, optimized software production and traceability.

Gaetano Cantalupo added, “Over the years, Comau has dedicated itself to research and development in the field of electrification. To help NEV customers meet the challenges of the future, we are committed to continue investing in the local market, developing innovative, cutting-edge products and solutions for manufacturing, and accompanying and leading the wave of new energy markets and technologies.”

During the speech, Gaetano Cantalupo and the technical managers answered attendees’ questions and opened a lively discussion around the relevant topics. The visitors also toured the Innovation Centre and went deeper into the plant’s production line and shop to get a more intuitive understanding of Comau’s comprehensive smart manufacturing offer